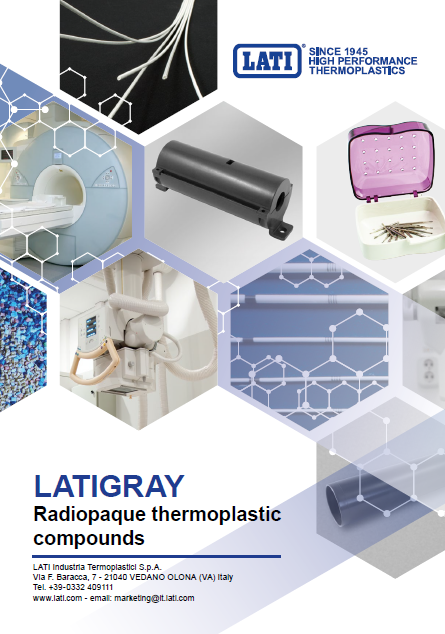

X-rays are increasingly used in technologies for the medical sector, security, and industrial diagnostics. The need to shield or detect objects with increasing precision makes the use of reliable, safe, and modernly processable radiopaque materials essential.

LATIGRAY are precisely a range of radiopaque thermoplastic compounds, designed to offer different levels of shielding, with the advantage of being non-toxic, easily processable, and suitable for injection molding.

LATIGRAY can be formulated to achieve:

- contrast detectability e.g., for medical tracers or diagnostic instruments,

- total radiation shielding e.g., for X-ray tubes, industrial devices, or protected environments.

The materials are based on resins selected for thermal, chemical and radiation resistance, including PPS, PEEK, PSU and PA12, and are loaded with variable quantities of ceramic or metallic powders, particularly tungsten for the highest performance versions.

Winning Characteristics

Safe Alternative to Lead

Adjustable Radiopacity

High Density, up to 11 G/Cm³

High Temperature Compatibility

Excellent Processability

Optical Detectability and Cytotoxicity Tested

Brochures and Catalogs

Replace Lead with LATIGRAY

From medical diagnostics to industrial safety, LATIGRAY is the high-performance answer for shielding or making your components detectable. Explore our database and discover the most suitable formulation.

Sectors and Applications

Learn more

F.A.Q.

Frequently Asked Questions

Many medical and industrial safety investigation techniques use X-rays. Radiation shielding is traditionally achieved with lead sheets or artifacts containing lead oxide. Replacing this problematic metal requires the introduction of alternative means with densities similar to lead. This is where LATIGRAY compounds come into play, designed to offer complete shielding or simple X-ray opacity.

Producing a compound with a density close to that of lead is complex and requires the dispersion of significant amounts of tungsten powder in the polymer matrix. Simple radiation opacity can be achieved with the same process but using less dense fillers, from ceramics to metallic powders.

Certainly. First, you must choose the most suitable radiopaque filler: ceramic, salts or metal oxides, steel powder. By then dosing the content of these fillers, you can achieve the desired contrast.

The excellent shielding effect of lead is due to its very high density of 11.3 g/cm3. Although the typical density of a polymer is close to 1 g/cm3, LATI’s extrusion and charge dispersion technology allows for the introduction of up to 96% by weight of tungsten powder into the molten polymer, thus obtaining compounds with densities close to 11 g/cm3

Exposure to gamma rays requires polymers capable of withstanding high-energy radiation. Polymers like PPS, PSU, and PEEK maintain mechanical and thermal properties even after irradiation up to 150 kGy.

LATIGRAY compounds are designed for injection molding of challenging geometries; however, it is advisable to evaluate the complexity of the problem on a case-by-case basis. Some solutions, such as tungsten-loaded grades, can be molded even on thin thicknesses, while others, like certain ceramics, require a bit more attention.

For prolonged exposure to X or gamma radiation, it is better to opt for PPS and PEEK.

There are radiopaque formulations specifically designed for use in the medical field. Contact our technicians for further details regarding cytotoxicity tests in case of potential contact with the human body.

X-ray shielding, as well as magnetic detectability, can also be achieved on elastomeric matrices and flexible polymers such as TPE, SEBS, or other polymers.

The fillers that LATI introduces into its compounds are chosen to minimize corrosion and abrasion effects on equipment. Naturally, ceramics and metal powders require attention during molding, especially concerning the feeding system sections. Our technicians are available to resolve any doubts in this regard.

The radiation shielding effect depends, in addition to the nature and percentage content of the radiopaque filler, also on its dispersion and the thickness of the walls crossed by the rays. LATI always recommends conducting tests in conditions as similar as possible to the real usage situation.

There are parameters, such as the half-value thickness, that are not immediately and easily usable. The simplest verification is to test samples, provided by LATI, with different levels of radiopacity, possibly overlapping them to reach the final thickness and irradiating them with the X-ray beam of the intensity that will be used (generally from 30 kGy upwards).

CASE STUDY, WEBINAR & MORE

Discover the Latest News about our Radiopaque Thermoplastic Materials

Radiopaque Filament for 3d Printing

3D printing as an industrial production tool is becoming a reality thanks to the rapid evolution affecting not only hardware equipment and control software, but also the resins used for filament extrusion.

Non-toxic Radiopaque Compound for Medical Devices: Innovation and Safety

Present for several years in LATI’s special products portfolio, LATIGRAY X-ray opaque and shielding compounds now offer an additional possibility to meet the requirements of the medical sector