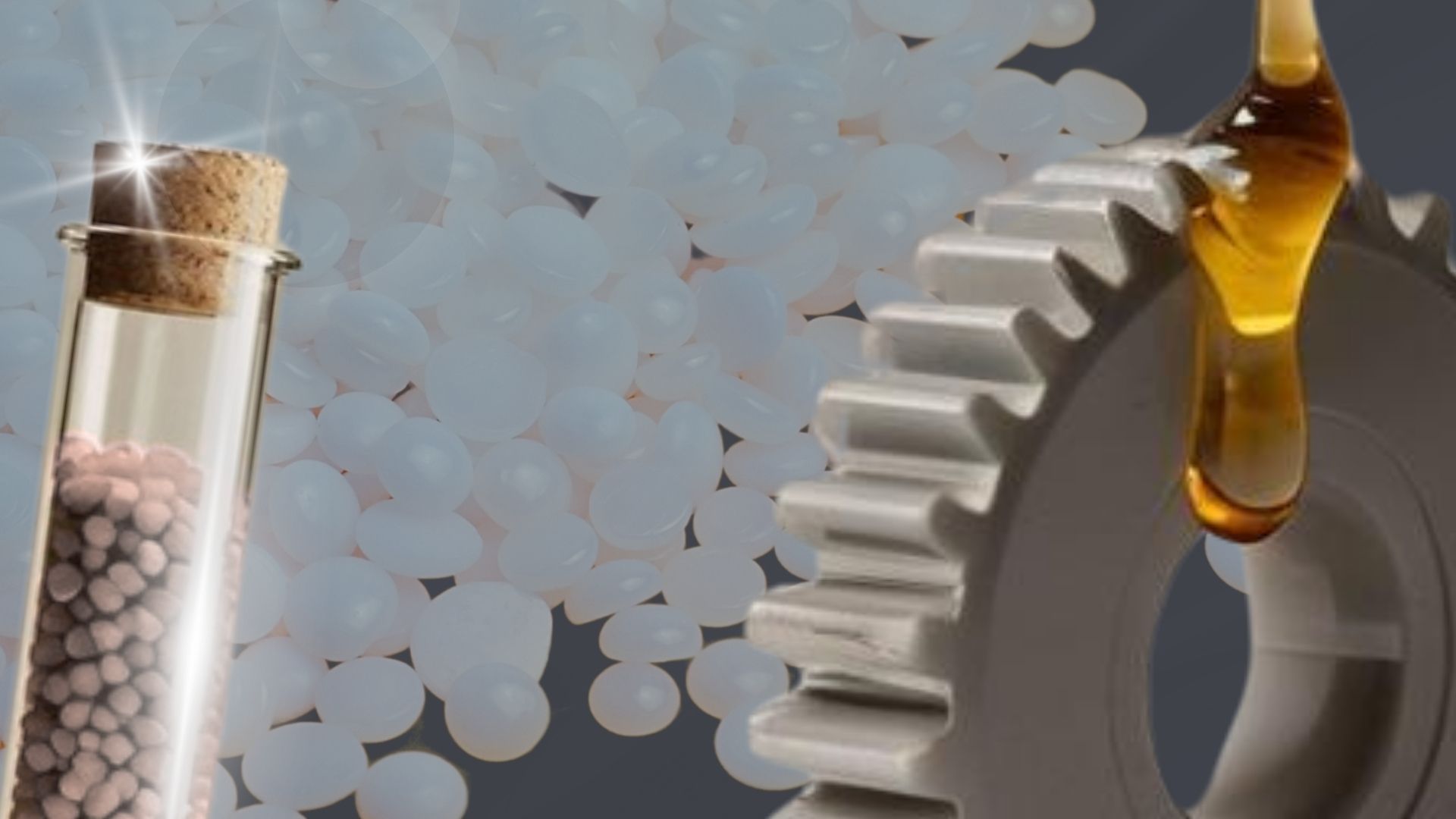

LATILUBs are designed to eliminate friction and wear issues in mechanical components subjected to relative motion. LATILUB formulations are developed on every polymer in the LATI range thanks to specific functional additives introduced to:

- reduce friction: molybdenum disulfide (MoS₂), silicone oil, graphite

- contain wear: aramid fibers

- raise the PV limit: carbon fibers, ceramics

- maximize performance: PTFE and PFAS-free alternatives

The result? Compounds with extraordinary tribological performance, reinforced and non-reinforced, operating without external lubricants and thus requiring no maintenance.

Used in complex and demanding applications, even at high temperatures, LATILUBs replace metals and ceramics ensuring lightness, design versatility, and long-term stability.

Winning Characteristics

Dry Self-Lubrication

Reduction of Friction and Wear

Reduced Noise

Design Freedom and Functional Integration

Chemical and Environmental Resistance

Efficient and Sustainable Production

Brochures and Catalogs

Choose LATILUB Compounds for Reliable, Low-Maintenance Applications

Thanks to LATI’s experience in self-lubricating compounds, it is now possible to create lightweight, durable components with very low friction coefficients and wear factors, even for extreme operating conditions. No maintenance, maximum reliability.

Sectors and Applications

Learn more

F.A.Q.

Frequently Asked Questions

LATILUBs are materials composed of a polymer matrix in which specific additives are dispersed to reduce friction and wear phenomena generated by relative motion between two or more contacting parts. LATILUB formulas are designed to ensure proper operation without resorting to external lubricants, e.g., oil or grease.

Anywhere there are friction and wear issues: Gears and sprockets, bushings, bearings, sliding planes, linear guides, cams, pins, mechanical elements for automation, automotive, pumps, valves, components in contact with water, plastic parts coupled with metal.

These are two different phenomena with some common causes, such as events of micro-adhesion between the materials of the elements in relative motion. Managing friction and wear requires a specific and optimized approach for the problem to be solved.

It is essential to identify not only the working temperature but also the local pressure conditions and relative speed that will characterize the application’s operation. Based on the usage scenario, the resin, any reinforcement, but above all the most appropriate self-lubricating system can be selected.

LATI has developed a very effective self-lubricating system based on various alternative additives, including ultra-high molecular weight polyethylene (UHMWPE), an advanced polymer that replaces PTFE in formulations developed on matrices transformable up to 300°C, for example, PA6, PA66, PPS. The LATILUB PTFE-free proposal is continuously evolving, contact our technicians for further insights.

With the same surface finish, it is possible to identify, at least broadly, PTFE as the most effective self-lubricating additive for reducing friction and aramid fibers as the best solution for abrasive wear problems. Graphite is an excellent proposal for very dimensionally stable self-lubricating elements, even in contact with water. Molybdenum disulfide allows for friction reduction even in reinforced compounds for applications sensitive to final cost.

LATILUBs are designed to operate without external lubrication. This means that maintenance of the lubricating gap will not be necessary and thus the system’s performance will remain consistent over time. Additionally, there will be no issues of dirt accumulation and consequent malfunctioning caused by dust captured by oil and grease.

In both cases, these are data obtained with semi-empirical measurements that simulate rather specific operating conditions. It is therefore advisable to consult these factors possibly under the same test conditions and for comparison between different products. It is best to avoid adopting these values as design specifications.

Certainly. The most performing solutions from a tribological point of view, such as PTFE and aramid fibers, work excellently even in matrices that transform at very high temperatures and operate beyond 200°C like PPS, PPA, and PEEK.

It is possible to ensure a reduction in friction coefficient and wear factor even in compounds reinforced with significant percentages of glass and carbon fiber perfectly suited for metal replacement projects. Interesting solutions are proposed on PP, PA, PPS, and PEEK bases. Note: the presence of fibers can promote abrasive wear on metal counterparts. Any glass and carbon particulate can then form very abrasive sludge in the presence of grease or oil. These materials should therefore be carefully evaluated before deciding on their use.

All LATI materials are designed to minimize negative effects on equipment. Carbon fibers are potentially very abrasive and PTFE tends to form deposits and promote corrosion if plasticized at temperatures above 300°C. The problem is managed by adopting appropriate steels and correct processing conditions.

CASE STUDY, WEBINAR & MORE

Discover the Latest News about our Self-Lubricating Materials

Ottobock Chooses LATI to Enhance its Orthopedic Solutions

Webinar – PTFE-free Materials for Self-Lubrication

Overcome PTFE limitations! Discover sustainable and advanced self-lubricating materials with LATI.

Self-lubricating Plastic Compounds and PFAS: Let’s Take Stock

PTFE is a polymer known for its very low coefficient of friction, a characteristic exploited in compounds loaded with PTFE powders dispersed in the thermoplastic matrix.

Askoll, Innovators by Nature

In a world increasingly focused on sustainability, companies are adopting strategies aimed at reducing resource consumption and minimizing the environmental impact of their products.

Webinar – Self-lubricating Compounds and PFAS. Let’s Take Stock

The extreme and widespread diffusion of self-lubricating plastic materials is due to the performance of these products, refined over the years thanks to the development of increasingly efficient formulas.

Self-lubricating Compound without PTFE: Innovation for Industrial Applications

The development of new special compounds has not experienced any setbacks, and many innovative formulations have been introduced into the LATI product range.