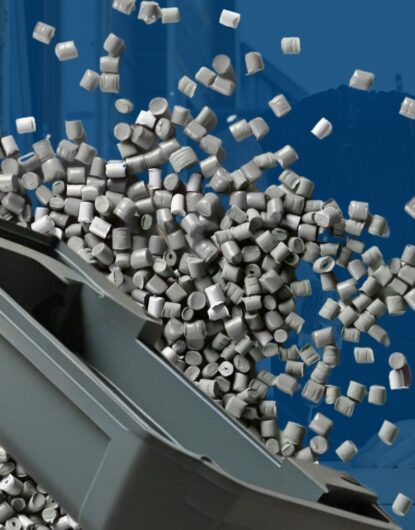

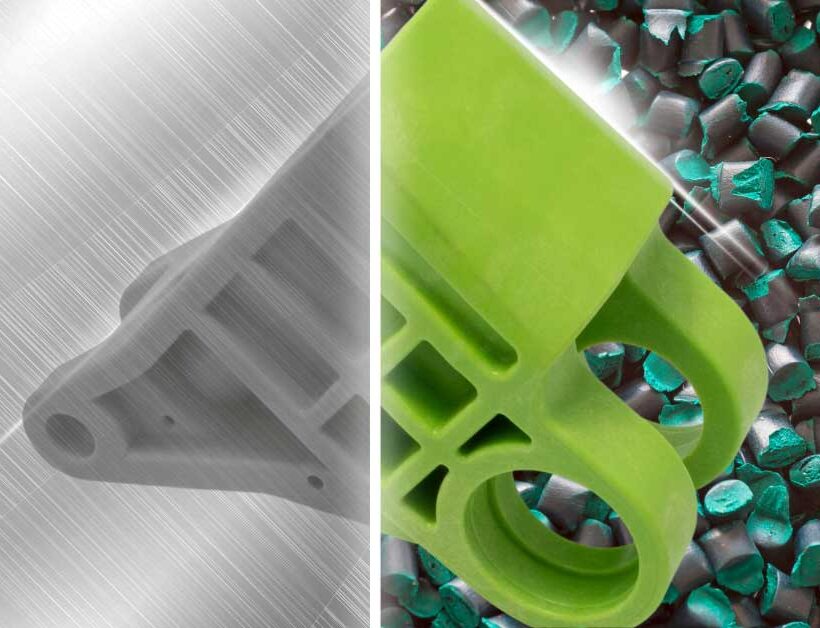

LATI’s reinforced compounds belong to the category of ETP (Engineering Thermoplastics), which are technical materials designed to combine interesting mechanical, aesthetic, and dimensional performance even in challenging environments.

Available based on polypropylene (PP), polyamide (PA), and polybutylene terephthalate (PBT), LATI’s ETPs include:

- Glass fiber reinforced materials, which ensure mechanical strength, impact resistance, and load resistance even over time.

- Mineral-filled materials such as talc, kaolin, or mica, ideal for improving dimensional stability and meeting geometric tolerances.

- Reinforced and toughened materials, to optimize the resilience of the products.

The range also includes versions with additional features such as:

- Custom colors

- Optimized fluidity for complex geometries

- Stabilization against heat, UV rays, and chemical agents

- Certifications for contact with drinking water and food

LATI’s reinforced thermoplastic materials offer an excellent balance between performance and cost, with wide flexibility in processing.

Winning Characteristics

Mechanical Strength

Dimensional stability

Protection from External Agents

Production Flexibility

Certified Safety

Do You Need a Robust and Reliable Technical Material?

Explore our material database to choose the most suitable reinforced thermoplastic compound for your application. Whether it’s dimensional precision, high mechanical performance, or certifications for food and water, you will find grades suitable for your needs. Otherwise, contact us.

Sectors and Applications

Learn more

F.A.Q.

Frequently Asked Questions

An Engineering ThermoPlastic (ETP) is a compound consisting of a polymer matrix of various types and one or more structural reinforcements, either fibrous or mineral-filled. These materials can be used wherever robust, mechanically resistant, and reliable parts need to be made. They are suitable for general use in various sectors such as appliances, automotive, and construction. And naturally, they are designed to offer excellent performance at an advantageous cost.

Amorphous polymers, such as PS, PC, ABS, and PSU, have very low dimensional shrinkage and are suitable for making dimensionally very precise products. Usually transparent, they can be transformed into compounds but are generally less versatile than semicrystalline polymers. The quality and lifespan of amorphous polymer products are greatly affected by the design of the geometry, the molding cycle, and the working environment: errors in these phases result in sudden failures due to stress cracking.

Semicrystalline polymers, such as PP, PA, PBT, PPA, PPS, and PEEK, offer very good mechanical properties even if not reinforced. They are excellently suited to being transformed into technical compounds of all kinds and for every application scenario, even in challenging environments. The crystallization process induces differentiated shrinkage that can result in significant dimensional contractions and deformations.

Glass fibers offer great improvements in terms of stiffness, mechanical strength, and resilience but, due to their morphology and elastic modulus, induce differentiated shrinkage and consequently deformations in molded parts. Mineral fillers contribute less to structural strengthening but, unlike fibers, increase the dimensional stability of products.

Wherever very tight dimensional tolerances are required, there are at least two options available: amorphous polymers, if the working environment and product geometry allow this choice, or semicrystalline materials filled with mineral fillers.

Reinforcing fibers induce differentiated shrinkage, the extent of which depends on the orientation of the fibers in the product. It is possible to manage this orientation by correctly choosing the position of the feed point, the filling speed, and the wall thickness to maximize the effects of holding pressure.

The resilience of polymers and compounds, especially at low temperatures, can be improved by dispersing a toughening phase, such as an elastomer, into the matrix. The viscosity of the base polymer can also affect the impact resistance of the material.

Suitability for contact with drinking water and food is possible by adopting materials formulated from selected raw materials. LATI has many technical compounds certified according to the most stringent European and international standards.

Compounds obtained from PP, PA6, PA66, PBT, or PC are always successfully colorable. The presence of large amounts of mineral fillers or reinforcements can compromise aesthetic results and color saturation. Some polymers have a natural color that needs to be managed: amber for PES and PPSU, brown for PEEK and PPS.

CASE STUDY, WEBINAR & MORE

Discover the Latest News about our Reinforced Materials

Webinar – Metal Replacement: Polymeric Solutions for Structural and Thermal Applications

Goodbye metals? When plastic does more

Replacing metals in technical applications? Here’s how to do it with thermoplastic compounds

LATIGLOSS 62 H2 GS/600: when Aesthetics, Strength, and Precision Coexist in the Same Compound

Askoll, Innovators by Nature

In a world increasingly focused on sustainability, companies are adopting strategies aimed at reducing resource consumption and minimizing the environmental impact of their products.

Robiaplast chooses LATI’s LARAMID T aromatic polyamides for its steam guns

Discover in the article how the collaboration with the LATI team led Robiaplast to identify the perfect material for its steam guns: glass fiber reinforced aromatic polyamides.