LATI’s magnetically detectable thermoplastic materials from the MDT range are designed to be detectable by magnetic metal detectors, X-rays or both simultaneously, even when present in very small fragments. Designed for applications in high hygiene-critical environments, such as food, pharmaceutical, and packaging, they represent an advanced solution against plastic foreign body contamination. Their characteristics also make them suitable for industrial safety applications.

Thanks to their metal fiber-free formulation, MDT compounds are safe, reliable and suitable for food contact, meeting the strictest European regulatory standards (EC Reg. 1935/2004) and American standards (FDA 21 CFR 177.2600).

The Advantages of MDT Materials

Guaranteed detectability with metal detectors and X-rays

No Contamination from Metal Powders

Food Contact Compliance

Compatibility with all LATI Resins

Simple Process Integration

Wide Choice of Colors, Including Food-Grade Blue

Brochures and Catalogs

Choose LATI MDT to Ensure Safety and Compliance

With over 40 available grades and customization options, LATI MDT materials offer maximum reliability in the food, pharma, and industrial sectors. The simplest way to avoid product recalls, image damage, and consumer health risks.

Sectors and Applications

Learn more

F.A.Q.

Frequently Asked Questions

There are many application sectors where detecting plastic elements is important: food processing, pharmaceutical sector, security. Plastic particles can contaminate food batches, forcing costly market recalls. Detectability by metal detector or X-rays of foreign elements can prevent this danger.

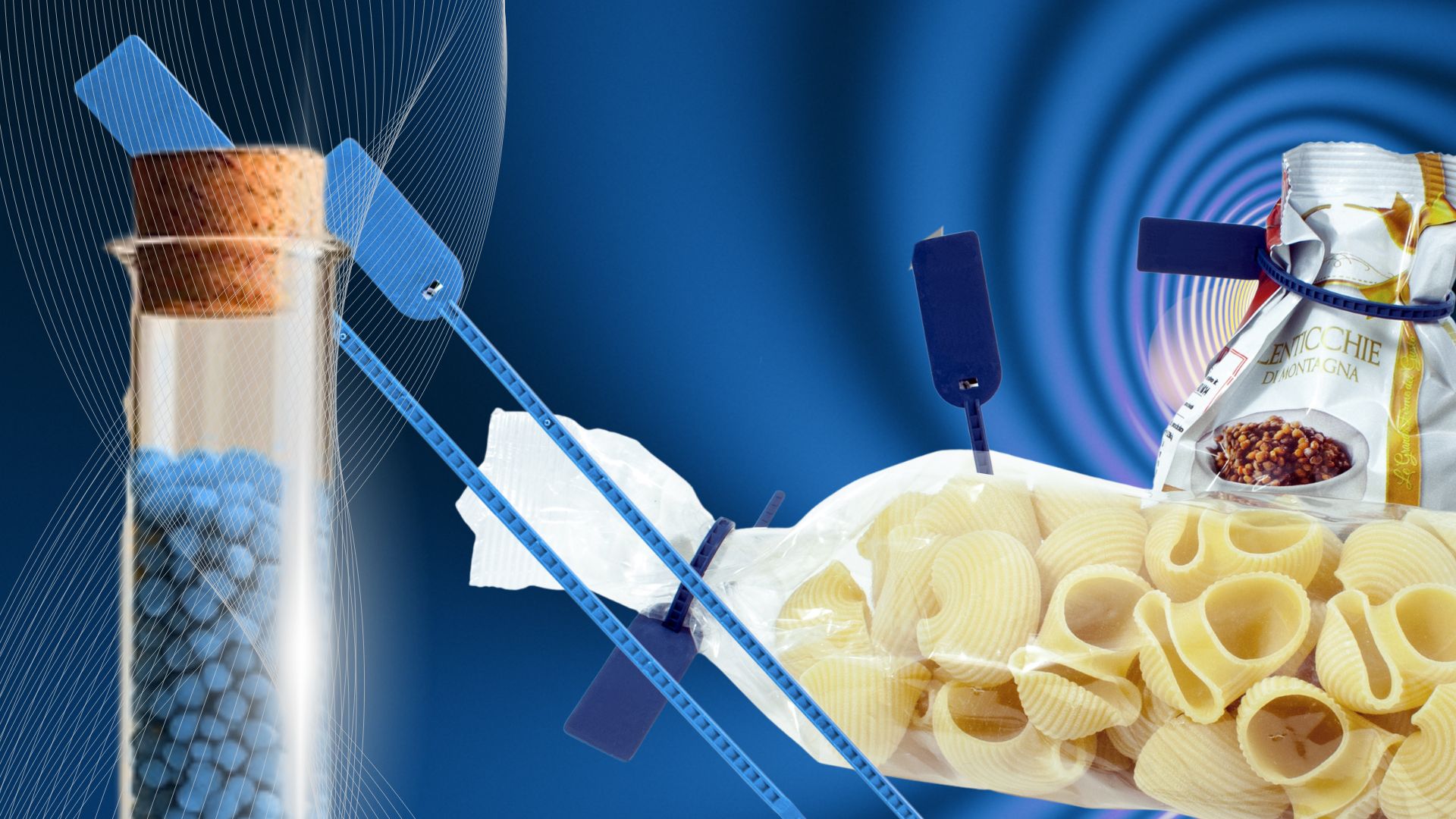

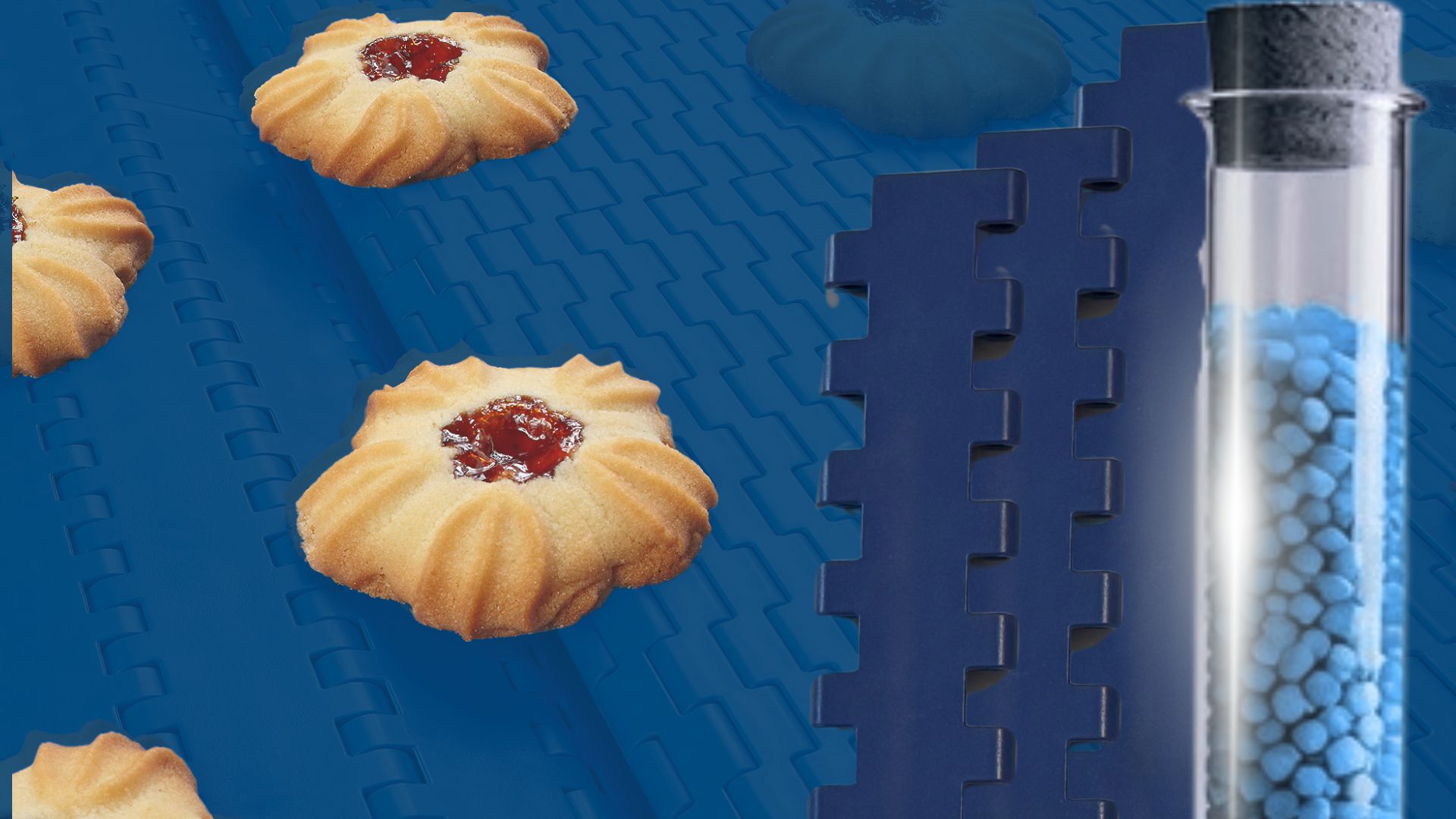

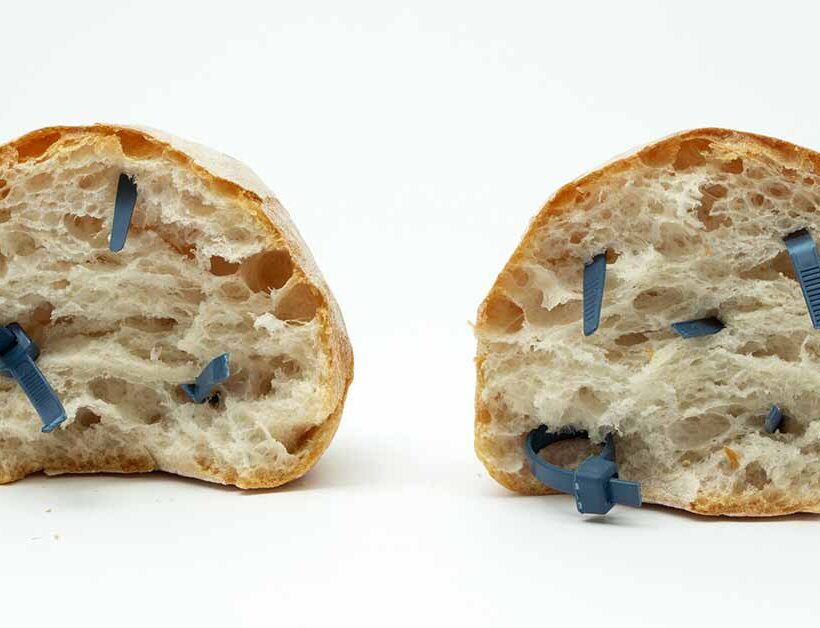

The detectability and technical characteristics of MDT compounds make them advantageous for use in critical sectors such as food and pharmaceutical for the production of parts such as: elevator cups, food conveyor belts and systems, durable and sanitizable fruit and vegetable crates, cable ties for automated systems, flexible or rigid tubes including for drinking water, thin films for gloves, aprons or covers, rigid modules and antistatic belts for modular systems, tools, housings, accessories and structural components, ovens and pasteurizers thanks to high-temperature grades

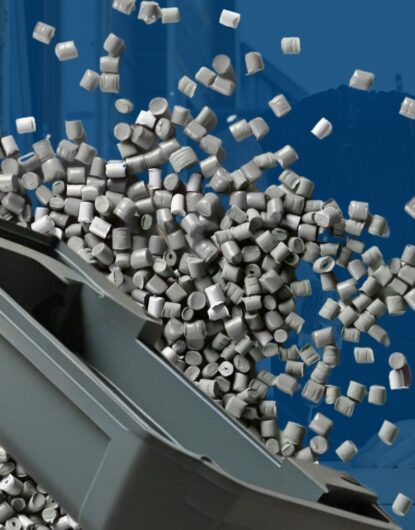

Polymers are not detectable by either magnetic field detectors or X-ray systems. By dispersing fillers of the correct density in polymer matrices, very small plastic particles become opaque to X-rays. Similarly, the use of appropriate ferromagnetic fillers can alter the magnetic fields of metal detectors used, for example, in food industry production lines.

MDT materials are detectable with all modern systems capable of detecting materials with low magnetic permeability. The MDT range includes materials simultaneously detectable by both magnetic field systems and X-ray equipment. LATI always recommends real-line testing because detectability depends on instrument sensitivity, type of filler used, size, shape, and orientation of the contaminant.

No, MDT materials are designed not to be permanently magnetizable.

To make a polymer detectable, significant quantities of special fillers must be dispersed, and consequently, the material’s mechanical strength may be compromised. Nevertheless, MDT formulations are designed for the best balance between impact resistance, robustness, colorability, and detectability.

By choosing appropriate polymer matrices, it is possible to have materials that are both detectable and flexible and resilient.

MDT compounds were specifically created to meet the need for greater safety in plastic parts used in food processing operations. Therefore, it is possible to have food-contact compatible MDT materials even in colors typically used in production lines, such as blue or gray. All MDT materials comply with EU Regulation 1935/2004 and, in many cases, also with FDA 21 CFR 177.2600.

The presence of considerable quantities of detectable fillers in MDT compounds limits the availability of these materials in all colors, especially lighter ones. However, colored MDT materials are available in darker saturated shades, such as blue, gray, black, etc. All while maintaining more than adequate mechanical performance.

Upon request, it is possible to formulate MDT compounds that also have excellent antistatic properties, perfect for example for dry food transport. Our technicians will be happy to illustrate all available options.

In MDT materials, the presence of significant quantities of detectable fillers naturally increases melt viscosity and reduces shrinkage during cooling. No significant abrasion or wear of equipment should occur. However, contact our technicians for further details.

LATI’s MDT formulations are primarily designed for injection molding, however, there are grades designed for thin film calendering and extrusion capable of surprising results.

CASE STUDY, WEBINAR & MORE

Discover the Latest News about our Magnetically Detectable Materials

Safer Food Conveyor Belts Thanks to Detectable Compounds

Metal detectable technical polymers for food processing: traceability and safety become standard in food contact plastic materials. The GANAL case study.

CEJN Chooses LATI Detectable Compounds: Stop Contamination!

Discover why CEJN has selected LATI’s detectable thermoplastic materials for the production of the new 208 Detect blow gun

Reliable Detectable Plastic Materials for Demanding Food Production Environments

In the highly regulated and demanding food sector, safety, durability, and hygiene are essential

Webinar – Detectable Materials for Safety Applications. Detectable Compounds

Detectable compounds for magnetic metal detectors or X-rays. How do they work? How are they used? What guarantees do they provide?

Detectable Compound for Food Industry: Safety and Contamination Prevention

A food product recall from the market can have very serious consequences for the manufacturer and the supply chain involved. The sale of contaminated food severely damages the image and reputation of an entire sector

Detectable Compound for the Food Industry: Prevention of Plastic Contamination

As is well known, the costs associated with recalling entire supplies of finished products from the market due to quality or safety issues can be truly substantial.