Innovation

Sustainability

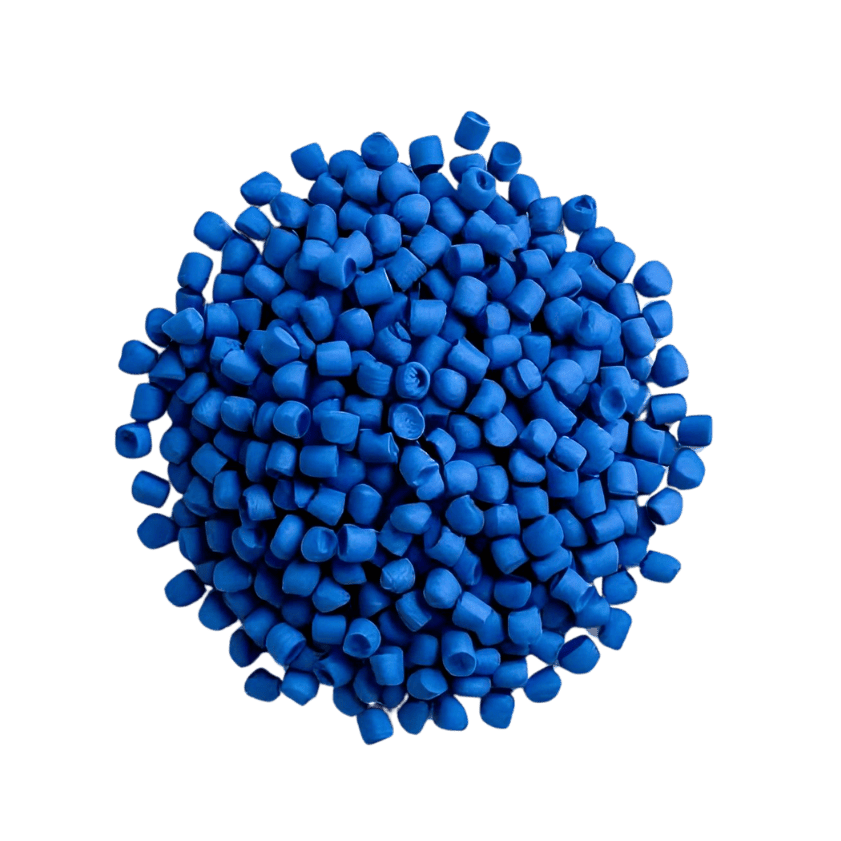

Thermoplastic materials

Ecovadis

Historic Brand

Great Place to Work

The Right Thermoplastic Material for Every Application

The LATI digital factory

Innovation and Sustainability at the Heart of Production

In our production hub in Gornate Olona, LATI has created a state-of-the-art factory that integrates technology, automation, and human expertise. Every stage of the process is designed to ensure quality, traceability, safety, and sustainability, making our production chain interconnected and highly efficient.

- Advanced technology: plants and systems interconnected with SAP to ensure traceability and precision.

- Sustainability: eco-friendly production chain with solutions that minimize environmental impact.

- Lean thinking: we reduce waste, simplify flows, improve every day.

- Continuous innovation: we constantly invest in digitalization and automation to optimize every phase of the production process.

+ 40 kton

Production Capacity+ 148 ML €

Revenue9 ML €

Ebitda+ 2500

FormulationsSystem Certifications

IATF 16949:2016

Quality

UNI CEI EN ISO 50001:2018

Energy

Operation Clean Sweep

Environment

UNI EN ISO 9001:2015

Quality

UNI EN ISO 14001:2015

Environment

UNI ISO 45001:2018

Health and Safety

UNI PdR 125:2022

Inclusion

Sustainability Report

LATI Sustainability: Innovating Responsibly towards People and Planet

About Us

Michela Conterno

Vittorio Gerola

Michela Limido

Chiara Ambrosetti

Alessandra Barozzi

Luca Bracca

Paola Cinzia Ciampi

Diego Imbrighi

Andrea Lugli

Alessio Portentoso

Luca Posca

Massimiliano Ravazzani

Laura Riva

Lorenzo Travagin

Andrea Lato

Loredana Mercante Garcia

Marta Clotet Planas

Jean-Luc Ernwein

Ben Hargreaves

Tobias Harscher

Henrik Orwen

Fabio Scandroglio

Kelvin Wu

Jan Styk

Gabriele Berzacola

Remo Bianchi

Stefano Borghi

Mariusz Borkowski

Caroline Brozyna

Alessandro Bruzzo

Philippe Ciniello

Tilo Diemand

Puting Feng

Victor Chen

Giuliano Grasso

Daniel Hernandez Pinilla

Tim Lai

Peter Chen

Davide Simone Larese Fece

Etienne Lemaitre

Rolando Mancilla Garcia

Rafal Parol

Marco Patricelli

Ludovic Pinguet

Massimiliano Sassi

Ralf Richard Schmied

Timo Schröder

Pericle Tancioni

Tiziano Vitali

50 +

Commercial Professionals with Technical Expertise, Distributed GloballyClient Reviews

With Approximately 2000 Satisfied Customers, Discover What They Say about Us!

“With LATI, we have found concrete solutions to our needs for innovation and high-tech materials, essential to ensure quality and sustainability in our devices”

Tiziano Barea

“With LATI, we have built a collaboration based on trust and innovation, thanks to their ability to customize materials for our needs, with a focus on sustainability”

Gabriele Gaida

“Thanks to the collaboration between Hexagro, LATI and Protool Plastics, we were able to address multiple challenges with a single solution: LATICONTHER”

Felipe Hernández

“LATI has proven to be an ideal partner thanks to their range of UL-certified products required by the North American market and their technical support in optimizing the molding process.”

Marco Bernardinello

Hexagro

Ergotech

BTSR

Askoll

Customer Champion:Celebrating our Successful Partnerships

- BTSR

- HEXAGRO

- ASKOLL

- ERGOTECH

BTSR and LATI: a successful partnership for over 20 years

Since 1981, the two companies have joined forces to develop advanced technical solutions, using the best materials to ensure excellent performance in industrial applications. Go to video- Continuous collaboration

- Innovative materials

- Commitment to sustainability

LATI and Hexagro: innovation and sustainability

Hexagro chose LATI for high-performance thermally conductive materials, optimizing energy efficiency, heat dissipation, and reducing environmental impact. Go to video- Innovative project

- Thermally conductive materials

- Commitment to sustainability

Askoll and LATI: together for a greener future

Askoll, a leader in the electric motor sector, chose LATI to support production optimization in Mexico and for the development of products in advanced plastic materials. Go to video- Customized training

- Flame retardant and self-lubricating materials

- Commitment to sustainability

LATI and Ergotech: collaboration in automotive

The partnership between LATI and Ergotech led to the development of a plastic diesel fuel filter, designed for the automotive sector. Go to video- Automotive sector

- Electrically conductive materials

- Sharing values

Our Values

Know-how

Plastic materials are an invaluable resource. We cultivate and apply our know-how to ensure the proper production and use of this resource. Our success stems from our in-depth understanding of plastic materials, and we are continuously renewing and enriching this know-how. We constantly strive to raise the awareness of the public and of our customers to ensure the proper use of these invaluable materials throughout their life cycle.

Integrity

All our relations are based on reciprocal trust and mutual benefit and reflect a long term view of what we wish to achieve with our employees, business partners and customers.

Sustainable Development

We respect the environment, which we deem a common good. We are committed to environmental preservation through the relentless quest for innovative product and process solutions, and through the promotion of environmental sustainability wherever we operate. Our priority is qualitative, not quantitative growth. We seek to generate value through «decoupling»: sustainable growth that does not entail corresponding increases in environmental pressures.

Employment and Employability

The creation and maintenance of employment is a primary goal for our company. We continuously invest in our people to generate opportunities for personal and professional growth. We do so to drive growth both for LATI and for the labour market in general.

Participation

Internally, we involve our people In our strategic and operational choices. We believe that this is the most effective way to plan and manage the activities of our company. Externally, we actively participate as partners with our local communities, collaborating with institutions, business associations and civic organizations to drive economic and social development and prosperity.

Wellbeing

We want our employees to feel involved, stimulated and respected. We guarantee their safety and promote their psycho-physical health.

Awards and Ratings

Our Network

Latest News

Smart Plastics 2026 | LATI among the leaders in high-performance polymers

Electro-Plast 2026 | LATI solutions for electrical and electronic applications

PLASTPOL 2026 | LATI at the International Fair of Plastics and Rubber

FIP 2026 | LATI at the leading trade fair for plastics, composites, and rubber

INTERPLAS 2026 | LATI at the leading event for the plastics industry in the UK