Technical Polymers for Galvanic and High-Stress Environments

The chemical and galvanic industry represents one of the most complex contexts for polymeric materials, due to the combination of high temperatures, highly corrosive environments and intense electrical currents.

In these scenarios, the choice of material must guarantee mechanical resistance, thermal stability and chemical inertness even under extreme operating conditions.

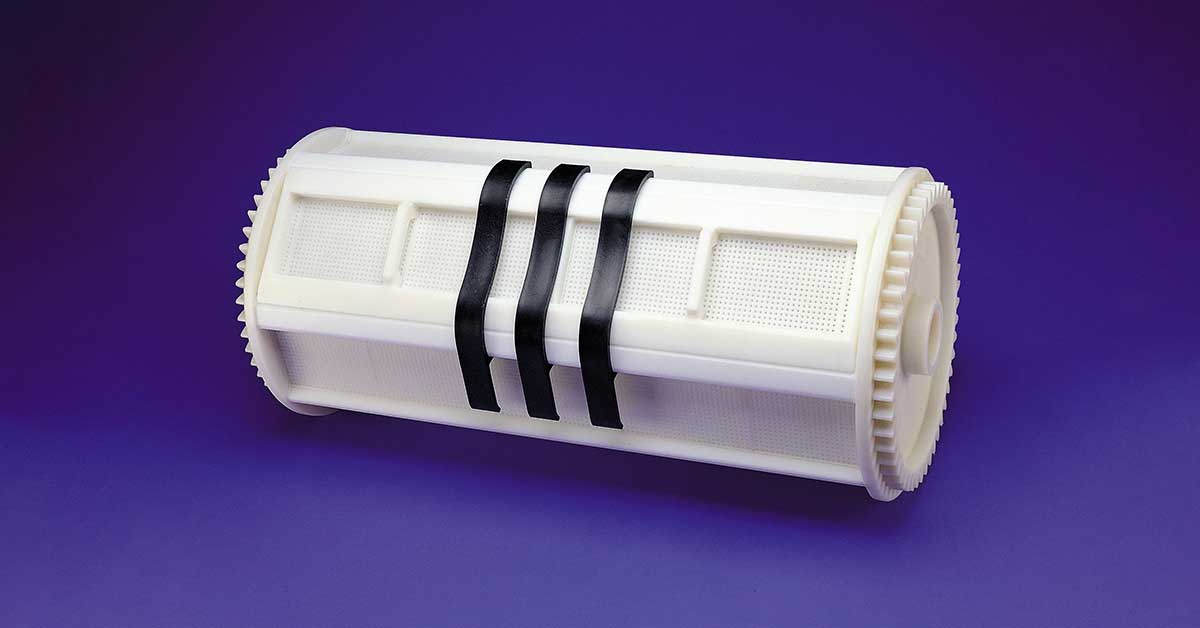

The experience of Progalvano, an Italian company leader in the production of rotary barrels for galvanic treatments, demonstrates how high-performance compounds can successfully replace traditional materials, such as PVDF, maintaining reliability and durability over time.

From Galvanics to Advanced Compounds: the Progalvano Project

In galvanic processes, the barrels mounted on rotors must resist not only the aggression of acidic and alkaline solutions, but also the presence of free ionic species and strong electrical currents.

Traditionally, Progalvano used polyolefins and fluorinated resins for the construction of its components, but new strongly alkaline-based processes required a more performant material.

The main challenge concerned the realization of the closing springs of the barrels:

- they had to maintain elasticity even at 100°C,

- resist creep and relaxation,

- offer mechanical stability over time,

- and guarantee chemical resistance to galvanic solutions.

LATENE Ag3h K/10: Carbon Fiber Reinforced Polypropylene

The solution was identified in LATENE AG3H K/10, a heat-resistant and mechanically reinforced compound based on polypropylene (PP) loaded with carbon fiber.

Main technical characteristics:

| Property | Typical value | Benefit |

| Base resin | High viscosity polypropylene | Thermal resistance and processability |

| Reinforcing filler | Carbon fiber 10% | High stiffness and elasticity |

| Operating temperature | Up to 100°C | Stability in prolonged use |

| Chemical resistance | Excellent | Inertness towards acidic and alkaline solutions |

| Creep resistance | Very high | No relaxation under load |

The field tests confirmed that the new springs produced in LATENE AG3H K/10 fully meet the design specifications, offering:

- superior operational durability compared to PVDF,

- greater residual elasticity,

- and absence of mechanical degradation after long usage cycles.

From Galvanics to Electronics: the Synergy with Thermally Conductive Compounds

Although the Progalvano case concerns chemical-mechanical resistance, the formulation technologies of advanced compounds, such as those based on carbon fiber or graphite, are the same used also for thermally conductive compounds for LED and electronic devices.

Both applications share similar objectives:

- Heat management or electrical resistance,

- Maintenance of mechanical properties at high temperature,

- Dimensional stability over time,

- and longevity in aggressive environments (humidity, heat, chemicals).

This convergence demonstrates how engineering thermoplastics can effectively replace metals and fluoropolymers, improving performance and sustainability.

Advantages of Reinforced Technical Compounds

| Category | Benefit |

| Thermal performance | Resistance up to 100°C without deformation |

| Mechanical durability | High elasticity and structural stiffness |

| Chemical compatibility | Inertness towards acids, bases and solvents |

| Processability | Injection molding and geometric customization |

| Sustainability | Weight reduction and production complexity reduction |

Thanks to these advantages, fiber-reinforced compounds and graphite-based thermally conductive compounds represent today one of the most promising frontiers for industrial mechanics, electronics and process chemistry.

Learn More

👉 Learn more about LATENE and LATICONTHER solutions for industrial, chemical and electronic applications.

Consult the technical data sheets on www.lati.com or request personalized consultation for your project.

FAQ – Thermally Conductive and Reinforced Compounds for Industrial Environments

- What is the difference between thermally conductive and reinforced compounds?

The former improve thermal dissipation, the latter increase mechanical resistance; both can be combined for complex applications. - Can LATENE AG3H K/10 replace fluorinated materials such as PVDF?

Yes, it offers comparable thermal and chemical performance with lower costs and weight. - Are these compounds also suitable for electronics and LEDs?

Yes, the presence of carbon fibers and graphite provides thermal conductivity and dimensional stability ideal for heat sinks or LED components.