Self-lubricating compound for industrial automation: high performance and zero maintenance

Robotics and Advanced Materials: the Challenge of Wear

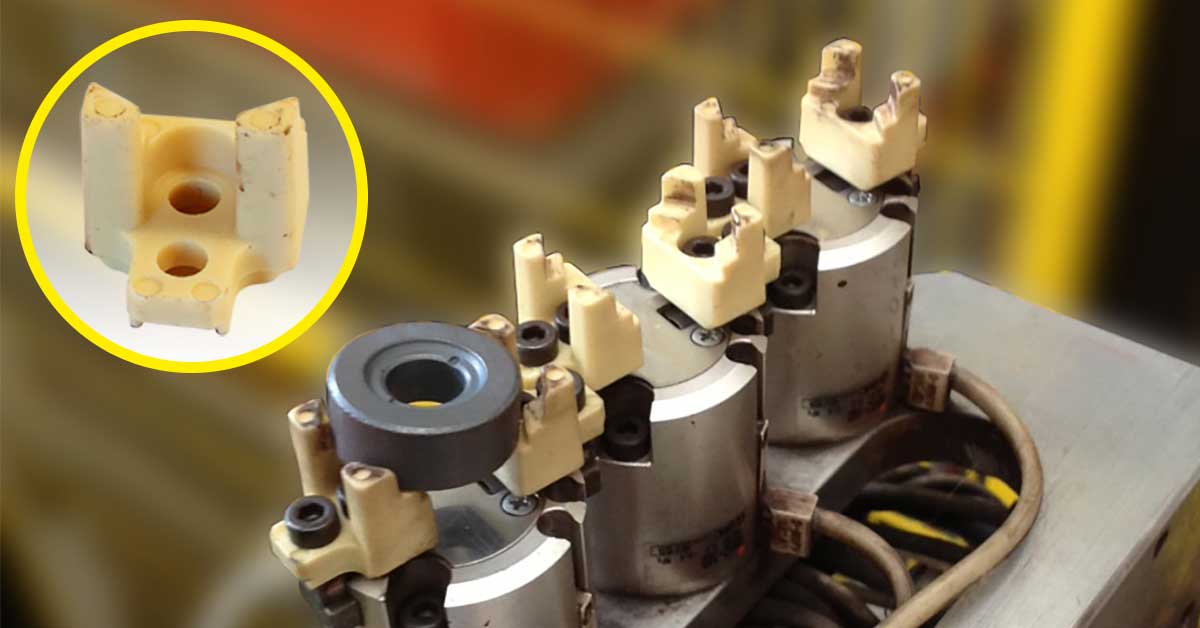

In the field of industrial automation, the reliability of gripping systems is essential. Anthropomorphic robots, engaged in object manipulation, perform

From Metal Powder to Self-Lubricating Compound

To solve the problem, the component was completely redesigned: the company Saroplast chose to replace the metal with a next-generation self-lubricating thermoplastic compound, the LATILUB 66-10T Y/15.

This material is composed of:

- PA66 as the polymer matrix,

- 10% PTFE (Teflon) to reduce the coefficient of friction,

- 15% aramid fibers to increase wear resistance.

Concrete Benefits in Robotic Applications

The use of the LATILUB self-lubricating compound has led to significant improvements:

|

Characteristic |

Advantage over metal |

|

Coefficient of friction |

Much lower thanks to PTFE |

|

Wear resistance |

Increased with aramid fibers |

|

Dimensional stability |

Comparable to metal |

|

Quietness |

Superior, no noise during cycle |

|

Costs |

More economical in production |

|

Maintenance |

From every 4 weeks to zero |

The new technopolymer jaws ensure a longer operational life without compromising precision and mechanical integrity.

Versatile Materials for Every Need

LATI offers the same self-lubricating formulation on different thermoplastic resins to cover every technical requirement:

|

Polymer base |

Typical applications |

|

PPS |

High temperatures and chemical environments |

|

POM |

High smoothness and precision |

|

PPA |

Resistance to continuous loads |

|

PEEK |

Extreme performance and long life |

FAQ

When is it advisable to use a self-lubricating compound in robotic systems?

When the application involves cyclic contacts and high wear, as in robotic jaws.

Does PTFE compromise the mechanical properties of the material?

No, if properly combined with reinforcements such as aramid fibers.

Is it possible to use these materials on multiple molds?

Yes, thanks to the excellent fluidity of the compound during molding.

Contact Us

If you are considering solutions to replace wear-prone metals in automated environments, LATI self-lubricating compounds represent a reliable, high-performance, and low-maintenance choice.

Contact us for a technical consultation or to develop a customized application.