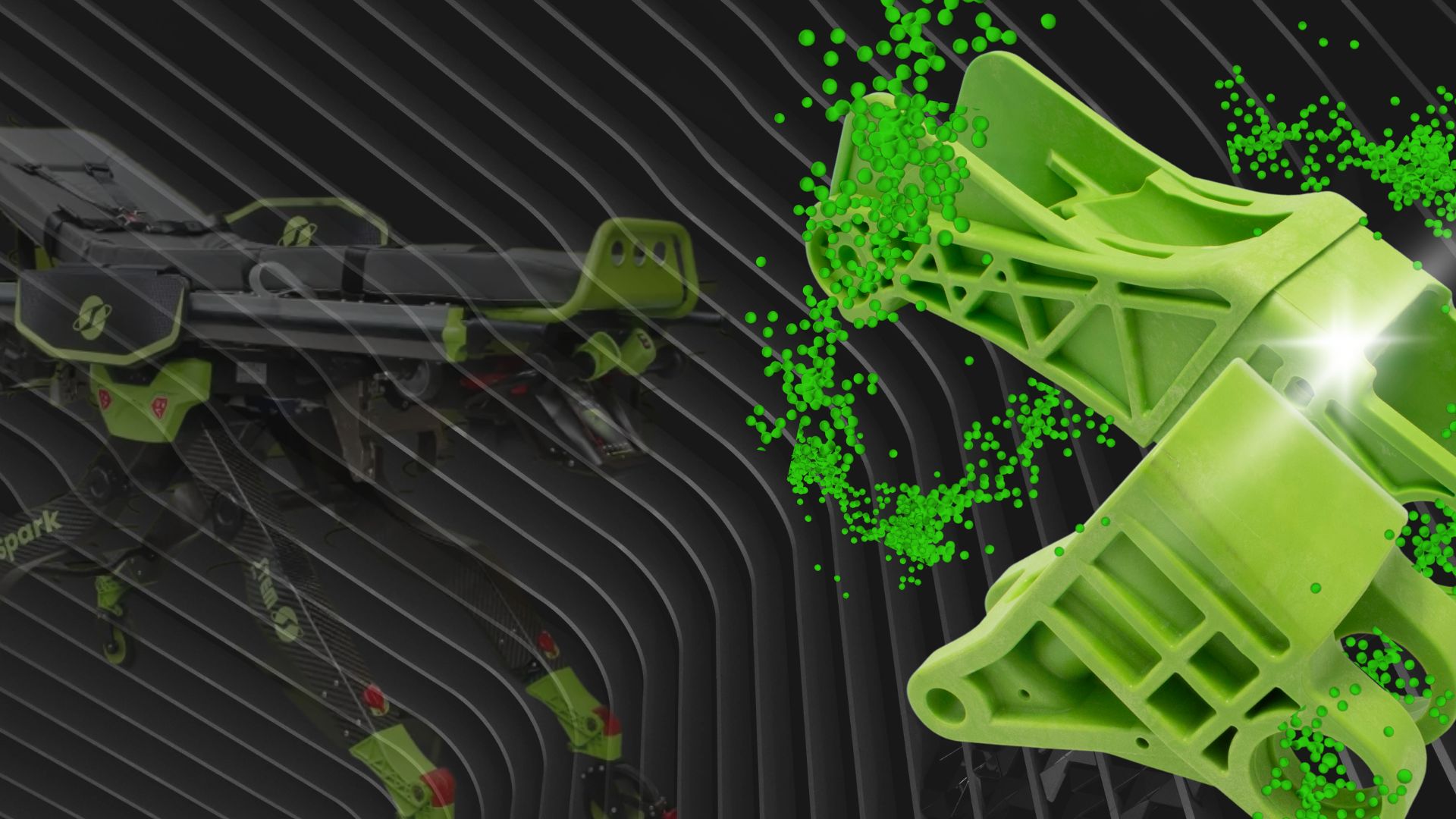

LATI structural compounds represent the most effective alternative to metals in applications where mechanical strength, rigidity and long-term reliability are required. Thanks to glass and carbon fiber reinforcement, these materials guarantee high performance combined with the intrinsic advantages of polymers: lightness, chemical resistance, design freedom and simpler processing.

LATI offers a wide range of structural technopolymers, formulated on matrices ranging from polyamides (PA6, PA66, PPA) to high-performance materials (PPS, PPA, PEEK), each with specific characteristics to handle static and dynamic loads, high temperatures, chemically aggressive environments. To combine robustness and aesthetic requirements, here are the LATIGLOSS grades.

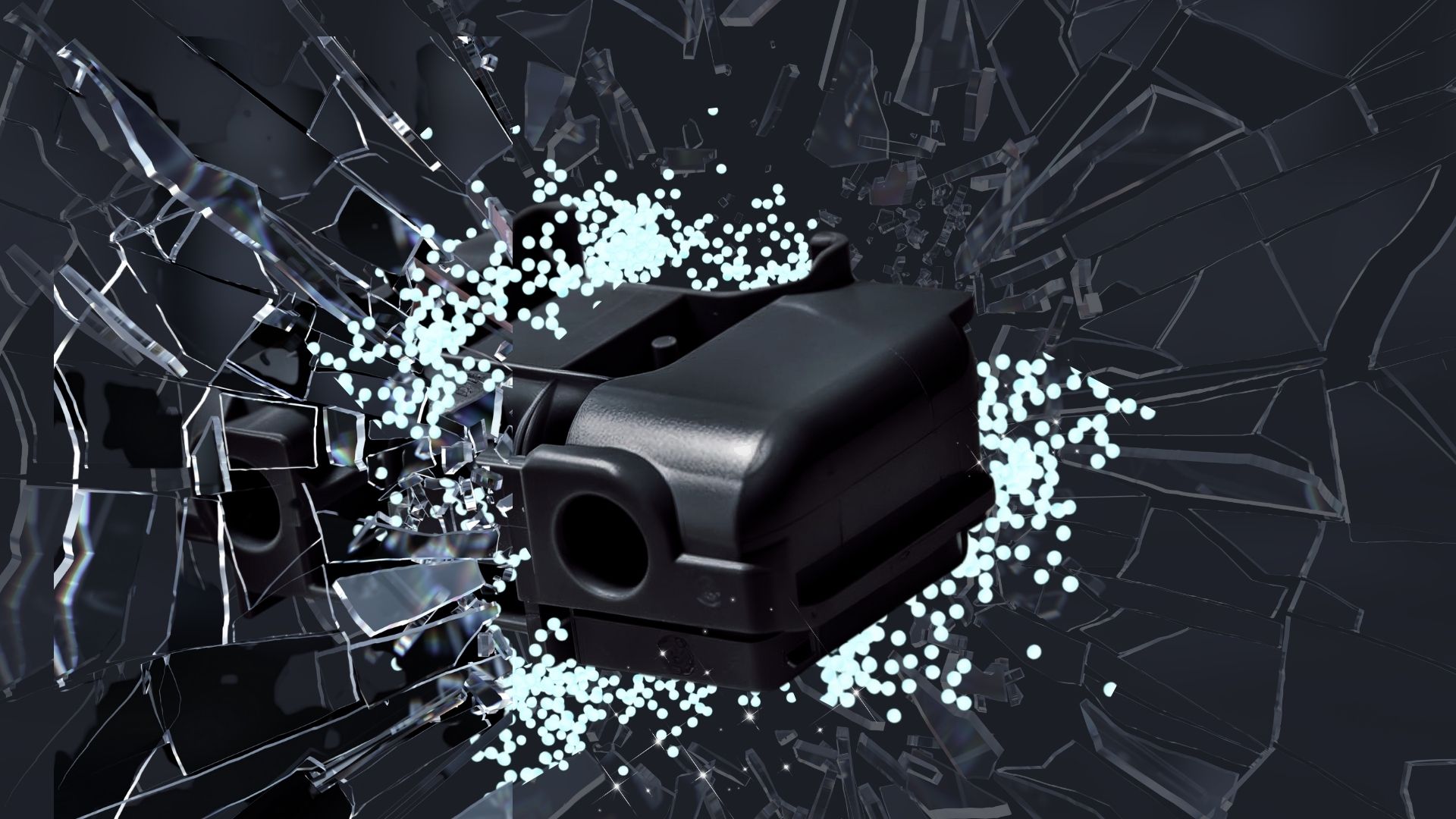

With LATI compounds, it is possible to replace metal elements such as zamak, aluminum and steel, or even ceramics and composites, in numerous industrial applications, reducing weight, costs and production time.

Winning Characteristics

High Mechanical Performance

Metal Replacement

Thermal Resistance

Dimensional stability

Aesthetics and Functionality

Complete Technical Support

Brochures and Catalogs

LATI PRODUCTS GUIDE Engineering Thermoplastics - Flame Retardant - High Performance

Want to replace metal? Discover LATI structural materials

Explore the materials database to choose the ideal structural compound for your application. High performance, refined aesthetics and complete technical support.

Sectors and Applications

Learn more

F.A.Q.

Frequently Asked Questions

Polymers reinforced with glass and carbon fibers can offer breaking stress and elastic modulus values comparable to those of metals such as aluminum and zamak. Furthermore, resistance to working conditions can benefit from the chemical inertness typical of plastics. However, it is essential to design the geometry of the products and the molding process in order to make the best use of the peculiarities and performance of matrices and reinforcements. Applying methods and criteria typical of metals to structural compounds is profoundly wrong and potentially dangerous.

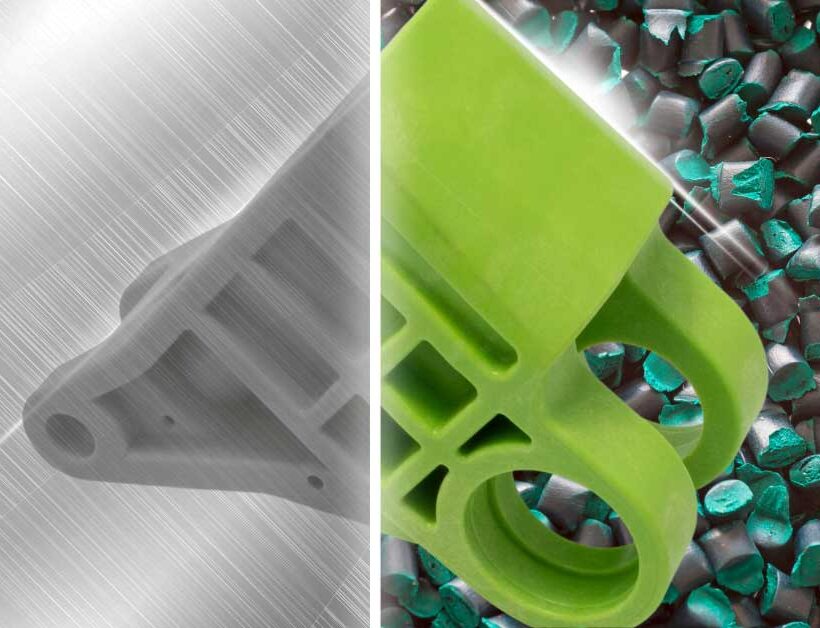

Generally speaking, a very high glass fiber content (over 50% by weight) will result in maximum values of elastic modulus and breaking stress: ideal for static applications where stiffness, long-term resistance and dimensional stability are priority aspects. If impulsive stresses are expected, it is better to prefer a lower fiber content, for example 40%. 50% glass fibers (or 40% carbon) constitutes a good compromise between the two application choices.

Certainly, LATI offers a wide range of structural materials suitable for metal replacement operations and at the same time suitable for contact with water and food. Grades based on PP, PA, PPS and PPA certified by the most important international institutes can be consulted here (insert link). Attention: at the moment there is no carbon fiber suitable for these situations.

Normally short reinforcing fibers tend to compromise the aesthetic performance of reinforced compounds, leaving characteristic streaks and spots on the surface. Progress has been made to improve the appearance of these grades: in particular, the range of structural compounds for aesthetic applications LATIGLOSS is now available. These are compounds developed on PA6, PA66 and PPA reinforced from 30 to 60% with glass and carbon fiber, capable of ensuring an absolute level surface finish. Consult our range

Glass fibers allow excellent strength and robustness to be achieved while maintaining a good performance/price ratio. Structural products with glass fibers are therefore excellent candidates for any metal replacement project. Compounds reinforced with carbon fibers are proportionally more rigid, electrically conductive, slightly self-lubricating and exclusively black in color: they are normally selected for applications requiring considerable mechanical performance, lightness, dimensional stability, antistatic properties.

Due to their nature, thermoplastic polymers tend to adapt their arrangement over time in order to minimize the internal stress state. This translates into an increase in deformation in the case of a constant imposed load (creep) or in the relaxation of internal tensions in the case of a constant imposed displacement. The phenomenon involves a sliding of the macromolecules that can be considerably hindered by the reinforcing fibers. To ensure reliable and safe performance for products subjected to constant stresses over time, it is therefore appropriate to adopt reinforced compounds: the higher the quantity of fibers, the lower the effects of viscous flow will be.

The high presence of reinforcing fibers naturally decreases the possibility of adding additional functional modifiers and additives. However, in the LATI range you can find compounds loaded at 40 or 50% with glass fiber and simultaneously self-lubricating, flame retardant, antistatic.

A constant load, even if very high, requires rigid materials with high elastic modulus, high breaking stress and excellent creep resistance. A dynamic stress, for example an impact, instead requires a material capable of distributing the imposed stress in order to absorb its energy through deformation. In the first case, therefore, you can opt for a highly reinforced material, even with carbon (e.g. 60% glass fiber or 40% carbon fiber); in the second case, you will instead opt for a lower reinforcement content (e.g. 30 or 40% glass fiber).

The problem of fatigue also exists in polymeric materials and is decidedly complex. Fatigue failure depends on multiple factors, including the type, frequency and amplitude of the stress (for example a vibration). In general, failure occurs following crack formation and subsequent advancement in the material. The presence of reinforcing fibers helps limit damage generated by possible local overheating and hinders crack propagation in the material.

FEM simulation software is now available with which it is possible to preventively evaluate the performance of an object made with structural compounds, correctly taking into account not only the boundary conditions (loads and constraints) but also temperature, time and environmental conditions. LATI offers its customers a complete co-design and feasibility verification service.

Glass and carbon fibers can be very abrasive and cause rapid wear on molds, nozzles, feeding systems and plasticizing elements. The phenomenon is faster the higher the speeds and stresses involved (elements that can also contribute to breaking the fibers themselves, reducing their effectiveness). It is recommended to adopt wear-resistant steels and surface hardening treatments where necessary, in addition to correct molding parameters.

CASE STUDY, WEBINAR MORE

Discover the Latest News about our Structural Materials

LATI in Renault 2025 Panel: Thermoplastic Compounds for Electric Mobility

LATI confirms its leading role in the transition towards sustainable mobility, with high-performance thermoplastics included in Renault Group’s A-PMR 2025 panel.

Webinar – Metal Replacement: Polymeric Solutions for Structural and Thermal Applications

Goodbye metals? When plastic does more

Replacing metals in technical applications? Here’s how to do it with thermoplastic compounds

LATIGLOSS 62 H2 GS/600: when Aesthetics, Strength, and Precision Coexist in the Same Compound

Reinforced Polyamide: the Lightweight and Durable Alternative to Aluminum in Gisowatt Vacuum Cleaners

More strength, less weight: the innovation of plastic materials for industrial vacuum cleaners