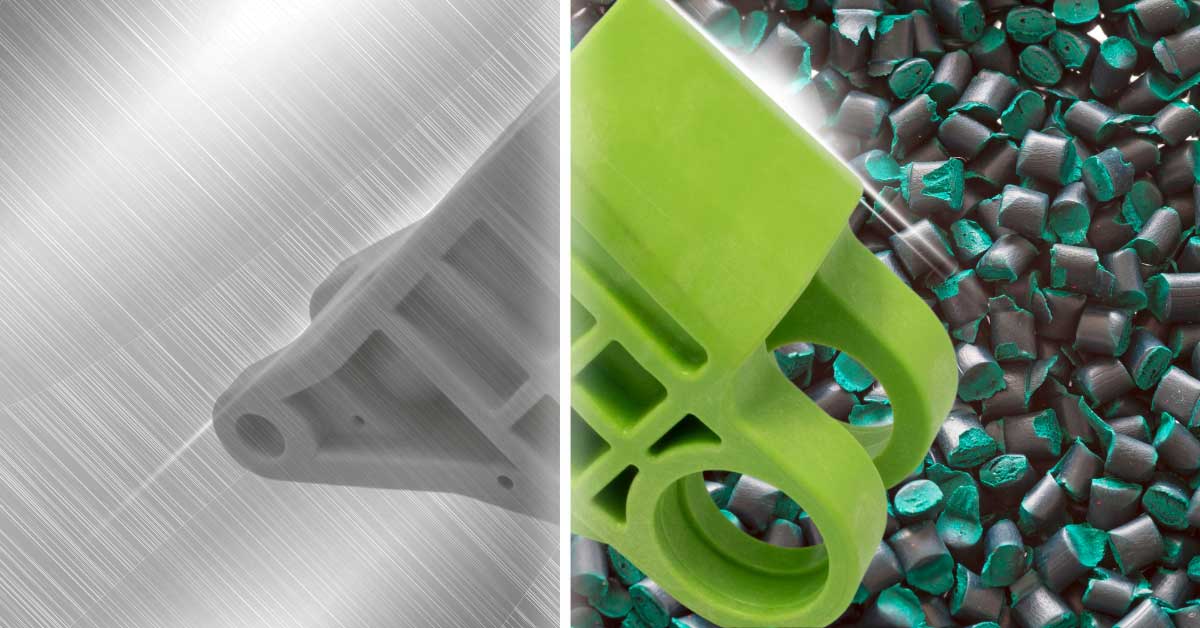

Tackling the metal replacement challenge with confidence through FEM simulation, technical expertise, and LATI specialty materials.

Why Replace Metals: Advantages and Complexities of Technical Compounds

In recent years, the need to reduce weight, cut costs, and improve sustainability has increasingly driven designers toward metal replacement: substituting metallic components with reinforced thermoplastic compounds. However, the transition is not without obstacles.

Unlike metals, polymers exhibit complex mechanical, thermal, and rheological behaviors, influenced by factors such as time and temperature. These aspects require a complete rethinking during design and molding phases.

From Metal to Polymer: the Design Challenge

Overcoming the Traditional Approach

Many technical products originate with a “metallic logic,” where isotropic properties and established processing methods simplify design. When transitioning to polymers, however, new variables emerge to consider:

Without proper support, the

LATI: Experience, Simulation, and Co-Design since 1995

Complete Engineering Support

Aware of the complexity inherent in metal replacement, LATI established a team of technical experts dedicated to co-design as early as 1995. Their mission? To support customers in preventive project validation with advanced tools and materials knowledge.

FEM Simulation and Real Data: the Power of Prediction

Using state-of-the-art FEM software and material behavior descriptions obtained in internal laboratories, LATI is able to:

- Simulate mechanical and thermal stresses, even over long periods;

- Optimize geometries and modify materials;

- Predict shrinkage, deformation, and residual stress during post-molding cooling;

- Drastically reduce waste of financial resources and time.

Designing with polymers? Now it’s simpler (and less risky)

Reduce Time and Costs, Increase Performance

The LATI approach allows tackling metal replacement with a predictive engineering method, avoiding errors during design or mold construction phases. This means:

- Cutting development time;

- Minimizing technical risks;

- Accelerating go-to-market with lighter and more sustainable products.

Start your Metal Replacement Journey Today

LATI has already successfully supported over 1,600 metal replacement projects through FEM simulation in sectors such as automotive, appliances, electrical-electronic, and industrial.

Contact our team for a free technical evaluation and discover how to best leverage LATI thermoplastic compounds to replace metals reliably, sustainably, and with high performance.