LATI’s thermally conductive materials from the LATICONTHER range represent an alternative to metals for heat transfer. Thanks to the presence of functional fillers such as graphite and special ceramics, our compounds achieve thermal conductivities exceeding 30 W/mK, while maintaining the typical characteristics of plastic materials: lightweight, moldability, chemical resistance, design versatility.

Designed to meet the needs of high-tech sectors such as automotive, power electronics, LED lighting, railway, and e-mobility, LATICONTHER offers a complete range of thermally conductive materials, electrically conductive or insulating, also available in flame-retardant versions and mechanically reinforced with glass fiber.

Thanks to their reduced density and the overall economy of production processes, LATICONTHER materials also represent a more sustainable solution compared, for example, to die-cast aluminum thanks to their lower carbon footprint.

The Advantages of Thermally Conductive Thermoplastic Materials

High Thermal Conductivity

Weight Reduction up to 50%

Excellent Processability

Chemical and Environmental Resistance

Electrical Insulation or Conductivity

- LATICONTHER CP: thermally conductive and electrically insulating, with color options available.

- LATICONTHER GR: both thermally and electrically conductive, with high performance due to high graphite content.

UL-94 Flame Retardant Certification

Sustainable Solutions and Low GWP Compared to Metal

Brochures and Catalogs

Choose LATI for your Next Thermally Conductive Application

With over 80 years of experience and a continuously evolving range, LATI is the ideal partner for technical, high-performance, and customized thermoplastic solutions. Our materials are designed for a more efficient, lightweight, and sustainable future.

Sectors and Applications

Learn more

F.A.Q.

Frequently Asked Questions

LATICONTHER materials are injection-moldable thermoplastics, consisting of technical polymers filled with large quantities of thermally conductive fillers. All LATICONTHER materials are designed to transport heat much more effectively than neat polymers, including casting resins.

There are two main types of thermally conductive compounds: those filled with graphite (GR) and those containing various types of ceramics (CP). Graphite-filled materials offer very high thermal conductivity values but are also electrically conductive, and for this reason, they should be used carefully in electrical/electronic applications.

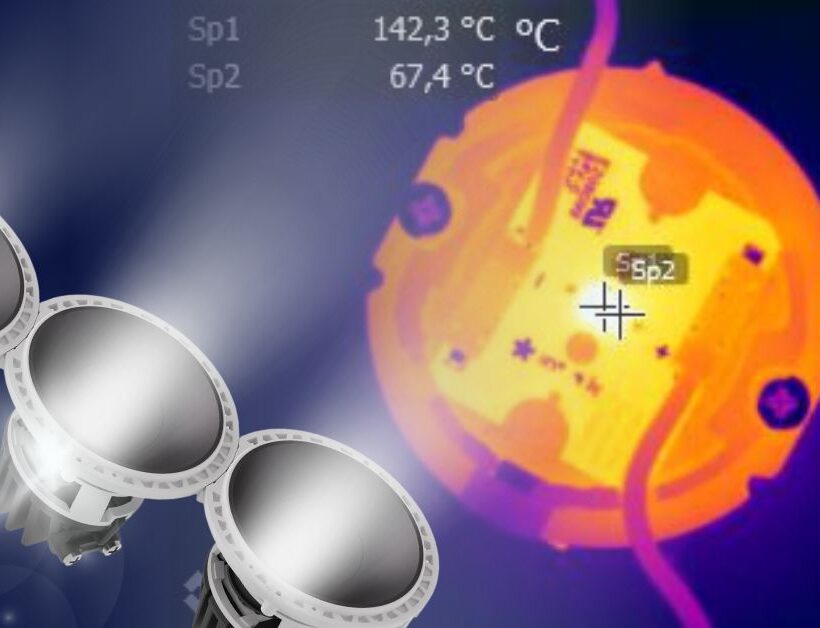

Wherever rapid cooling or heating is necessary: electronics, high-power LED lighting, sensors, heat exchangers, various housings and supports for electrical applications, power bar supports, e-mobility batteries, etc.

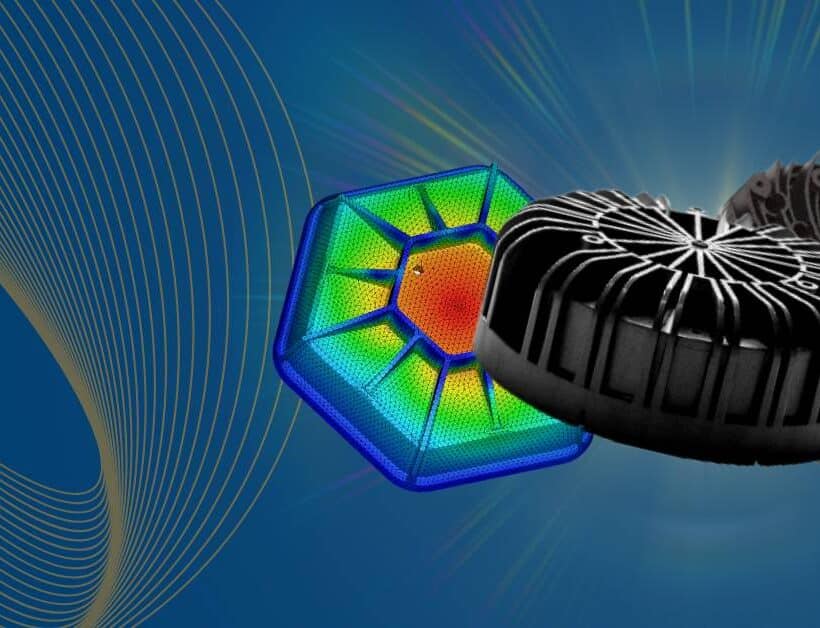

The thermal performance of LATICONTHER can be influenced by the wall thickness of the product. On average, you can count on a mean thermal conductivity of about 10-15 W/mK for graphite-filled compounds and 1-4 W/mK for ceramic-filled ones. Actual local values can be much higher. LATI measures thermal conductivity in three spatial directions using the LASER-Flash method (ASTM E1530, E1461-92).

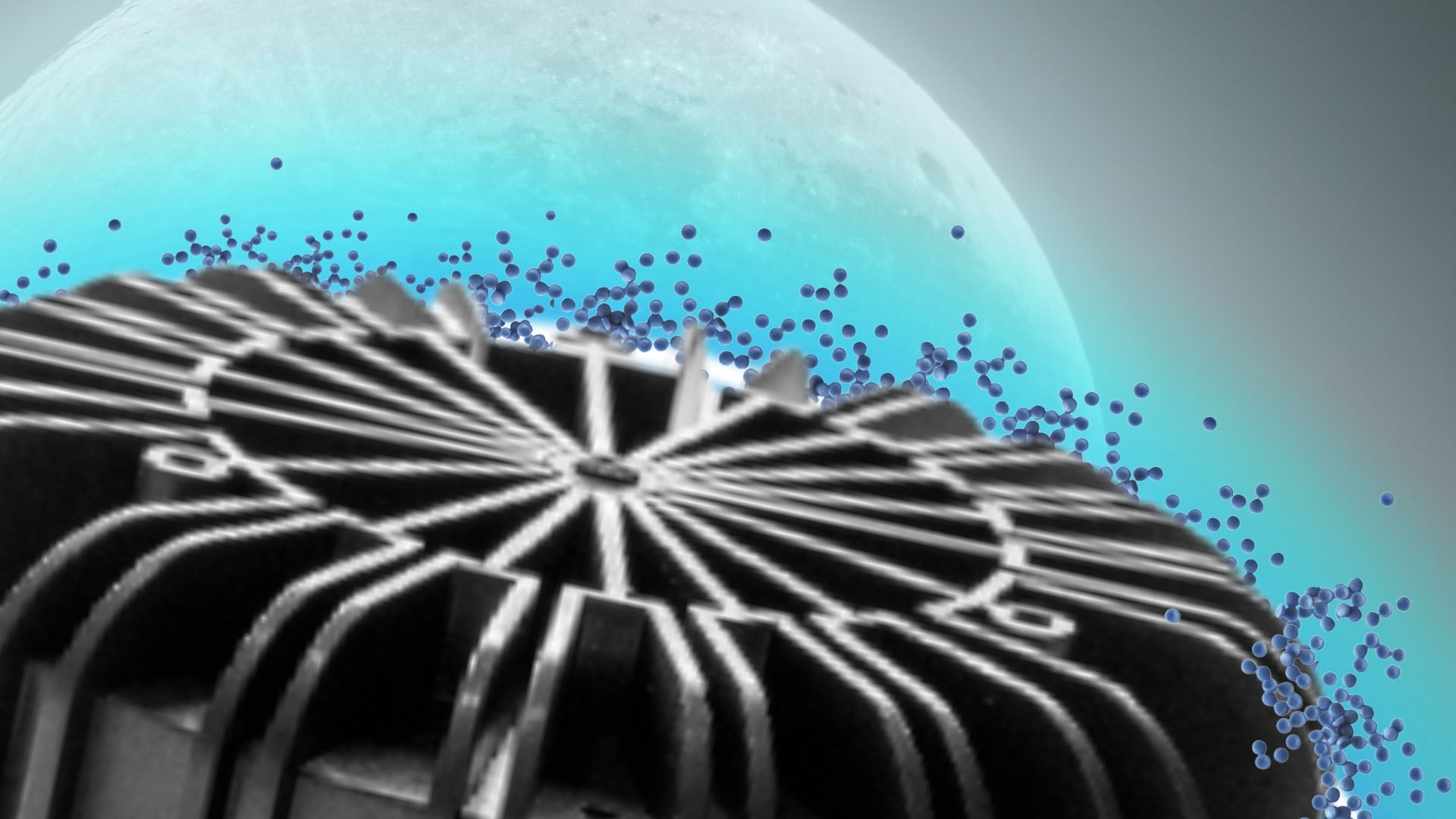

The conductivity of the compounds is lower compared to copper and aluminum, but if the heat sink operates under natural convection conditions (i.e., without forced ventilation), it can be verified that the use of materials with thermal conductivity above 10 W/mK has a lesser impact on the overall thermal performance of the assembly. It is therefore correct to choose LATICONTHER where heat transfer occurs through natural convection and radiation.

The main limitation is the operating temperature, which should not exceed the safety temperature for the polymer (generally below 150-200°C). Another limitation is the thermal power density: concentrated heat sources and/or very high powers should be avoided. Finally, it’s necessary to remember that the high amount of thermally conductive filler compromises mechanical strength, which must find the right compromise with project requirements.

LATI does not offer formulations that are particularly abrasive or corrosive to equipment. However, keep in mind that the amount of fillers present can exceed 80%, so it’s better to use anti-abrasion steels with high chromium and manganese content.

Plastic materials have an average density of 1.5, about half that of aluminum. They are very lightweight, require little energy for processing, and are completely recyclable. LATICONTHER molded products do not require any post-processing (de-gating, deburring, washing, painting, etc.). Obviously, the environmental footprint also benefits from these aspects, considering the advantageous GWP of thermally conductive compounds.

By appropriately choosing the base resin, it is possible to adopt thermally conductive solutions even in the presence of chemical attack, environmental humidity, UV radiation, etc.

There are also various flame-retardant LATICONTHER formulations available with certification.

Even if the price per kg of material may be higher than metal, it is necessary to evaluate the overall cost of the final product to appreciate all the savings allowed by LATICONTHER. The low density, lower energy consumption, recyclability, absence of post-processing, lower transport costs, longevity of equipment, and versatility of materials often translate into overall competitive costs.

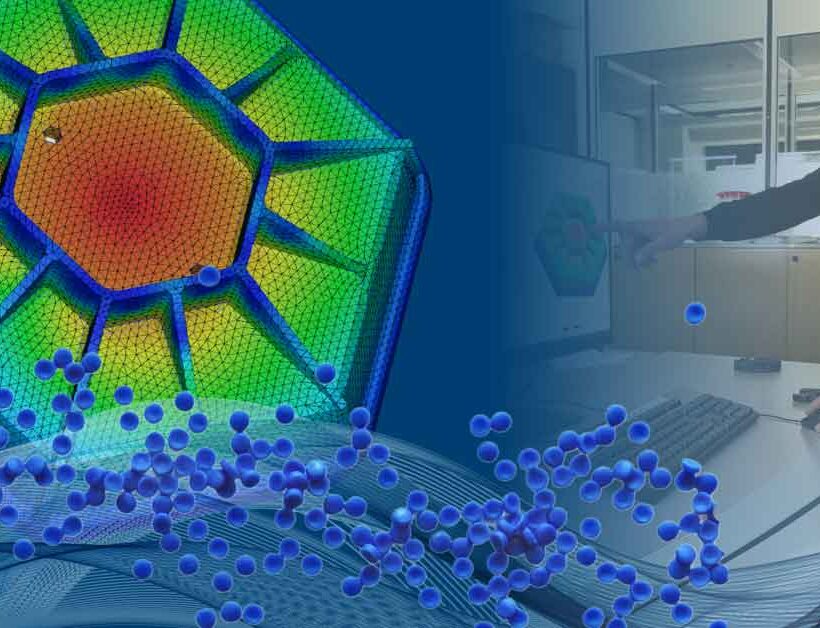

Certainly, LATI provides feasibility checks using FEM calculations that analyze the performance of the object in question under real operating conditions. It is crucial to emphasize that numerical simulations take into account the local thermal performance of the material influenced by the orientation of the conductive fillers.

CASE STUDY, WEBINAR & MORE

Discover the Latest News about our Thermally Conductive Materials

LATI in Renault 2025 Panel: Thermoplastic Compounds for Electric Mobility

LATI confirms its leading role in the transition towards sustainable mobility, with high-performance thermoplastics included in Renault Group’s A-PMR 2025 panel.

Vossloh Schwabe Chooses LATICONTHER for Street Lighting

The introduction of thermally conductive compounds in artificial LED lighting is now a reality that LATI has helped to build with over twenty years of field experience.

Thermally Conductive Plastic Materials in Lagolight Lamps

Explore the lighting revolution with Lagolight: discover how traditional materials have been replaced with advanced LATICONTHER thermally conductive plastic materials for the Fulgo portable lamp.

Conductive Plastic: Intra Lighting Chooses LATI for LED Light Heat Sinks

Intra Lighting, a leader in design lighting, faces the challenge of LED light heat.

Webinar – LATICONTHER. Sustainability and advantages of thermally conductive compounds

The LATICONTHER range is the best choice if you are looking for a thermally conductive material and a valid alternative to aluminum.

Webinar – Designing with Thermally Conductive Materials. Design Tutorial

How to best use thermally conductive compounds?