Technopolymers for Every Type of Industry

The countless applications intended for the industrial sector require high-performance materials suitable for use in extreme temperatures, wear, heavy loads, aggressive environments, and intense work cycles. All without compromising on safety and durability.

LATI offers materials capable of replacing metal, reducing the weight and costs of products while simultaneously improving productivity. LATI solutions combine mechanical strength, long-term reliability, chemical and thermal resistance, and self-lubrication. Each proposal can be customized according to specific needs.

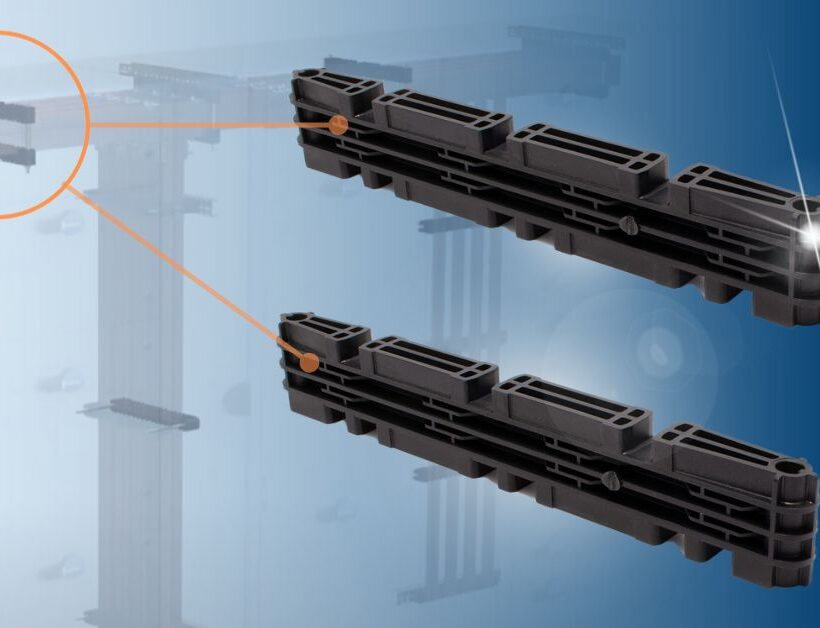

Conveyor Belts and Material Handling

In a world where logistics is gaining increasing importance, it is essential to be ready with structural, self-lubricating, flame-retardant, detectable, and antistatic proposals for the construction of conveyor belts and rollers.

- LATILUB self-lubricating compounds for guides, slides, rollers, and wheels. Perfect for reducing friction, wear, and noise while ensuring less maintenance and longer lifespan.

- MDT materials detectable by metal detectors and X-rays: ideal for applications in the food and pharmaceutical sectors, where traceability and prevention of plastic fragment contamination are crucial.

- Reinforced and antistatic compounds LATISTAT and LATIOHM: chosen for systems subject to significant mechanical stresses and for environments where electrostatic charge accumulation must be avoided.

- Structural flame-retardant grades for making rollers resistant to loads and suitable for fire risk prevention.

Hydraulics and pneumatics

The management of pressurized fluids requires great mechanical strength, dimensional precision, and robustness even in challenging environments, in the presence of temperature and chemical aggressors. LATI is ready for any challenge with:

- Structural materials for high pressure and temperature, designed based on PP, PA66, PPS, PPA, and PEEK and reinforced with glass, carbon, and ceramic fibers. Ideal for making valves, fittings, filters, compressors, and pumps of all kinds.

- With special polymers like PPS, PPA, PA9T, and PEEK, it is possible to handle not only air, hydraulic oil, or water but also technical gases, refrigerants, aggressive fluids.

- Certified solutions for managing drinking water.

Robotics

Not only robots and anthropomorphs used in industry but also exoskeletons and drones of all kinds. The future of machines serving the industry is filled with new challenges that LATI is ready to tackle with:

- Lightweight and strong structural materials, ideal for automation and for moving parts of frames, robots, drones, actuators. LATAMID, LARAMID, and LARTON are perfect for reducing inertia and improving performance and energy consumption in all kinds of mechanisms.

- LATILUB self-lubricating compounds for joints, hinges, sliding planes, manipulators, bushings, and bearings. Each solution is designed for real usage conditions.

- LATIOHM conductive materials and LATISHIELD shielding materials for protecting integrated electronics from the harmful effects of electrostatic charges and electromagnetic radiation.

Industrial Automation

The demands of industrial automation require materials resistant to wear, mechanical stress, and challenging environments. LATI compounds for this sector include:

- Structural compounds LATAMID, LARTON, and LARAMID reinforced with glass and carbon fibers to create lightweight and robust structural elements, also resistant to creep and fatigue.

- LATILUB self-lubricating materials to reduce friction, wear, and noise in mechanisms and guides.

- LATIOHM and LATISTAT antistatic compounds to prevent the accumulation of electrostatic charges wherever they could create hazardous conditions for people or equipment.

Textiles

The extremely high productivity of textile machines has pushed looms to an unimaginable level of technological sophistication.

- Structural compounds reinforced with glass or carbon fiber LATAMID and LARTON, to replace aluminum in arms, brackets, supports, and flanges, ensuring not only the mechanical strength of metal but also electrical conductivity that eliminates the risk of electrostatic charge accumulation, dust, and dirt on moving elements.

- LATILUB self-lubricating compounds ideal for moving parts subjected to intense and repeated stresses, even in the presence of dirt and chemically and thermally challenging environments.

- LATIOHM antistatic and colorable conductive materials

- Ultralight LATIMASS materials for high-speed moving parts

Safety and PPE

Whether firefighters, civil protection workers, miners employed in the extractive industry, or construction workers, all these figures need personal protective equipment to protect them from the risks present in the workplace. LATI solutions are numerous:

- Flame-retardant compounds to minimize fire damage.

- LATISTAT and LATIOHM antistatic or conductive materials to eliminate static charge accumulation, for example from equipment used in mines or wherever there is the presence of explosive ATEX atmospheres.

- LATISHIELD shielding compounds for protection against electromagnetic radiation of sensorized electronic PPE, for example, geolocation systems adopted by rescue teams.

- Toughened materials for helmets, masks, and other impact-resistant protections.

- Structural materials reinforced with glass or carbon fiber for supports, protective elements, respirators, etc.

Agriculture and Livestock

Even the production of food sources is rapidly changing to optimize productivity while reducing environmental impact. Both in agriculture and livestock, solutions are needed to make production processes more efficient, automated, sustainable, and safe. LATI materials are perfect for these needs:

- Grades suitable for outdoor use, resistant to UV rays, chemicals, and fertilizers, ideal for agricultural machinery and equipment.

- Structural materials for mechanically resistant and dimensionally stable elements, unaffected by challenging environmental conditions such as humidity and temperature.

- LATIOHM antistatic materials for safe operation in seed, flour, and feed processing plants and wherever potentially explosive dusts may be released.

Discover the Materials Designed to Tackle the Challenges of Industry Every Day

News and Events for Smart Production

Safer Food Conveyor Belts Thanks to Detectable Compounds

Metal detectable technical polymers for food processing: traceability and safety become standard in food contact plastic materials. The GANAL case study.

Lead-free Brass and Structural Compounds: Innovative Materials for a Safer Future

European regulations and growing public health concerns are accelerating the elimination of leaded brass, driving the industry toward alternative and innovative materials such as ecological alloys and structural thermoplastic compounds.

CEJN Chooses LATI Detectable Compounds: Stop Contamination!

Discover why CEJN has selected LATI’s detectable thermoplastic materials for the production of the new 208 Detect blow gun

Reliable Detectable Plastic Materials for Demanding Food Production Environments

In the highly regulated and demanding food sector, safety, durability, and hygiene are essential

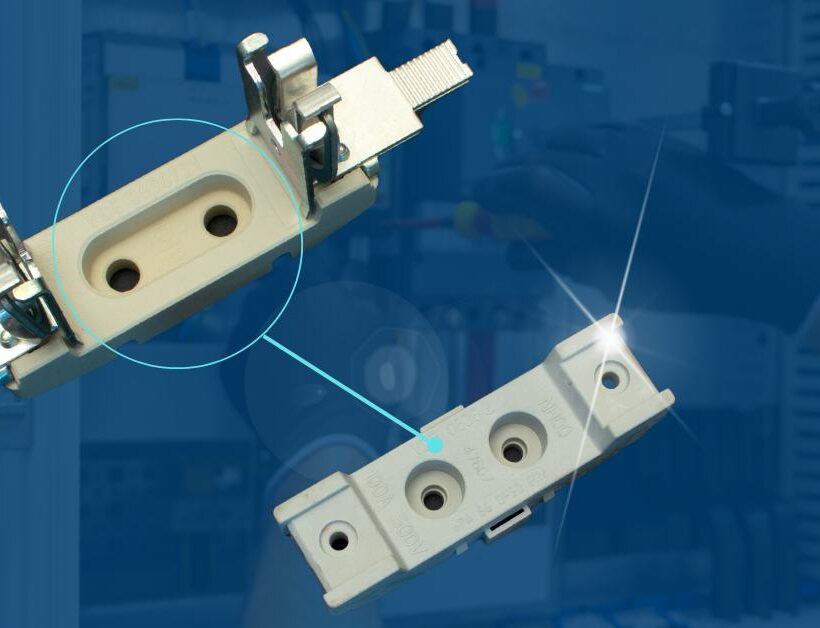

Self-extinguishing Materials for Electrical Energy Transport

The rapid development of high voltage and current applications requires new plastic materials resistant to operating conditions.

Plastic Materials for Distributing Electricity Safely and Sustainably – the EFEN Case

Discover how EFEN, a leading German company in the production of electrotechnical devices, decided to replace the ceramics used in its NG series fuse holders and switches with the LATI flame-retardant thermoplastic compound, LATAMID 66

F.A.Q.

Frequently Asked Questions

Maximum dimensional precision is achieved by loading base polymers with glass beads or mineral powders. The most dimensionally stable technical products are therefore available in the KELON range, in LATAMID loaded with glass beads, and in LARTON with mineral powder, such as LARTON GCE/650. Amorphous resins like PC and ABS provide excellent results, but their use for engineering applications must be carefully evaluated.

Yes, compounds based on PPS, PPA, and PEEK can withstand almost any type of chemical attack, obviously to be verified in real usage conditions.

The structural compounds that offer the best compromise between strength and toughness are obtained by loading the polymer with glass fiber up to 50%. Carbon fiber increases mechanical strength and stiffness but reduces resilience and elongation at break, while also being electrically conductive.

For applications requiring maximum stiffness, LATI offers compounds with high modulus carbon fibers such as LARAMID K/40 HM.