THE CHOICE OF MATERIAL

A winning project begins with the correct selection of the material to be used on which the mold, the production cycle and the design of the product are to be optimized. LATI offers its expertise in technical discussion at the customer, in the tailored formulation service, in co-design engineering, molding assistance and problem solving, as well as in training courses dedicated to the development of specialist technical knowledge also at the customer site.

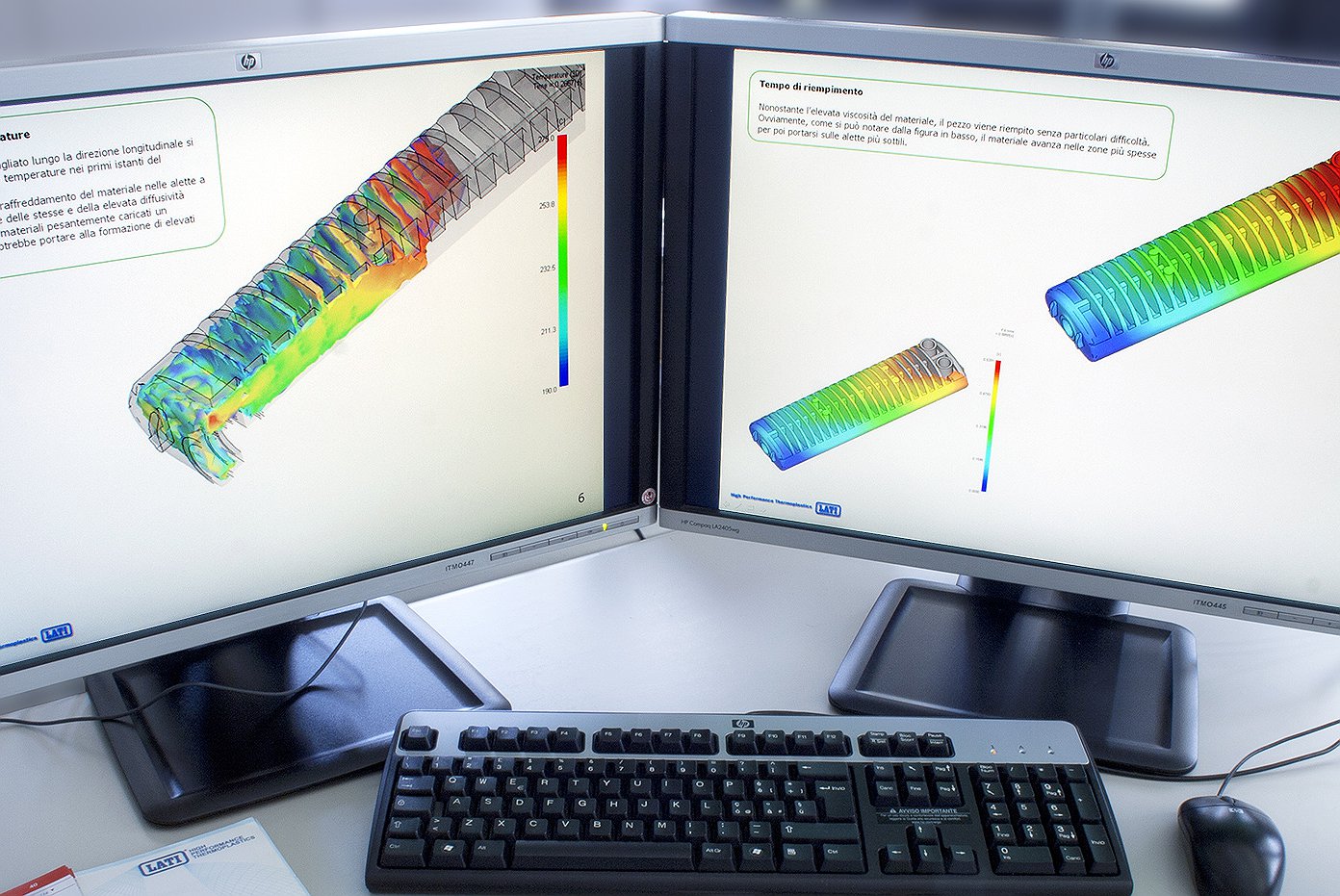

THE DEVELOPMENT OF CO-DESIGN PROJECTS

LATI offers its customers the opportunity to verify the validity of the projects through computer simulations obtained with state-of-the-art software and dedicated skills. It is possible to optimize not only the thermal and mechanical performance of the products, but also to correct the mold before it is built or to solve molding and deformation problems.