Metal-detectable engineering polymers for food processing: traceability and safety as new standards for food contact plastics

Ensuring the safety of the food we consume daily is a top priority for all companies involved in the collection, processing, packaging, and distribution chain. One of the most feared hazards is contamination by plastic fragments accidentally released from machinery used in food handling.

This risk is further complicated by the fact that traditional metal detectors cannot identify plastic particles, making it essential to use materials engineered to be detectable by advanced technologies such as magnetic field or X-ray systems.

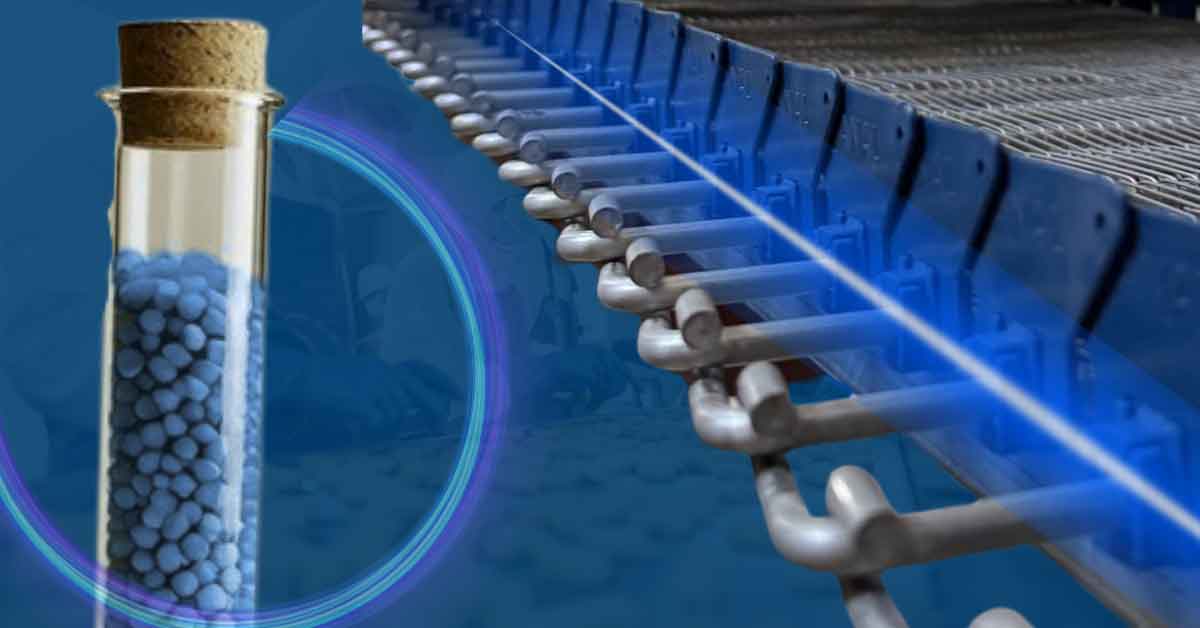

To address this challenge, LATI has developed a complete range of engineering polymers loaded with detectable powders, effective even in minimal quantities. These materials are known as MDT—Metal Detectable Thermoplastics—and are available in all types of polymer matrices: reinforced, filled, self-extinguishing, and even in the industry-standard blue color.

Spanish company GANAL, based in Valencia, recently incorporated LATI’s MDT materials into their industrial systems for the food sector, specifically using them for:

These solutions are widely used in food processing and must operate under harsh conditions: extreme temperature fluctuations, exposure to chemicals and disinfectants, and high mechanical stress—factors that demand resistant, stable, and detectable materials.

GANAL selected LATAN 13 MDT05-01, a POM (polyoxymethylene)-based compound enriched with detectable fillers predispersed in the molten mass to ensure maximum traceability.

Key advantages:

Through the website www.lati.com, GANAL was able to directly test MDT material performance on their own machines, confirming its suitability for their production needs.

Of course, both the base resin and the detectable fillers and colorants used in MDT compounds comply with regulations for direct food contact, meeting the most stringent hygiene and safety standards at European and international levels.

The collaboration between LATI and GANAL is a concrete example of how innovation in plastic materials can actively enhance food safety. MDT polymers reduce the risk of invisible contamination while delivering excellent mechanical and chemical performance essential to modern production environments.