The rapid development of applications with high voltages and currents requires new plastic materials able to withstand these operating conditions.

In the context of sustainable electricity generation and storage, or even just e-mobility, designers are required to come up with systems able to carry intense currents at both low and high voltages. Conveying large amounts of electrical energy requires large conductors, called busbars, which are sometimes contained in bus ducts.

The passage of very strong currents creates extremely harsh operating conditions for the materials supporting the busbars. First of all, they are heated, and can reach maximum working temperatures close to 100°C. And in the event of a malfunction, the temperature of the metal can easily exceed 400°C.

Furthermore, the electrical insulation, which is essential, must obviously guarantee operational safety in any situation. In the e-mobility sector, fire prevention requires compliance with specific performance levels in terms of flame behaviour and the glow wire test (GWIT according to IEC60695-2).

The bars must be held in place by solid supports able to withstand the mechanical and magnetic stresses caused by the current. To mould supports that will be reliable over time, LATI offers traditional well-established solutions, all certified as self-extinguishing under the UL94 V0 standard.

The polymers used are PA6, PA66 and PBT, made flame resistant thanks to red phosphorous-based, halogen-free and environmentally friendly retardant systems.

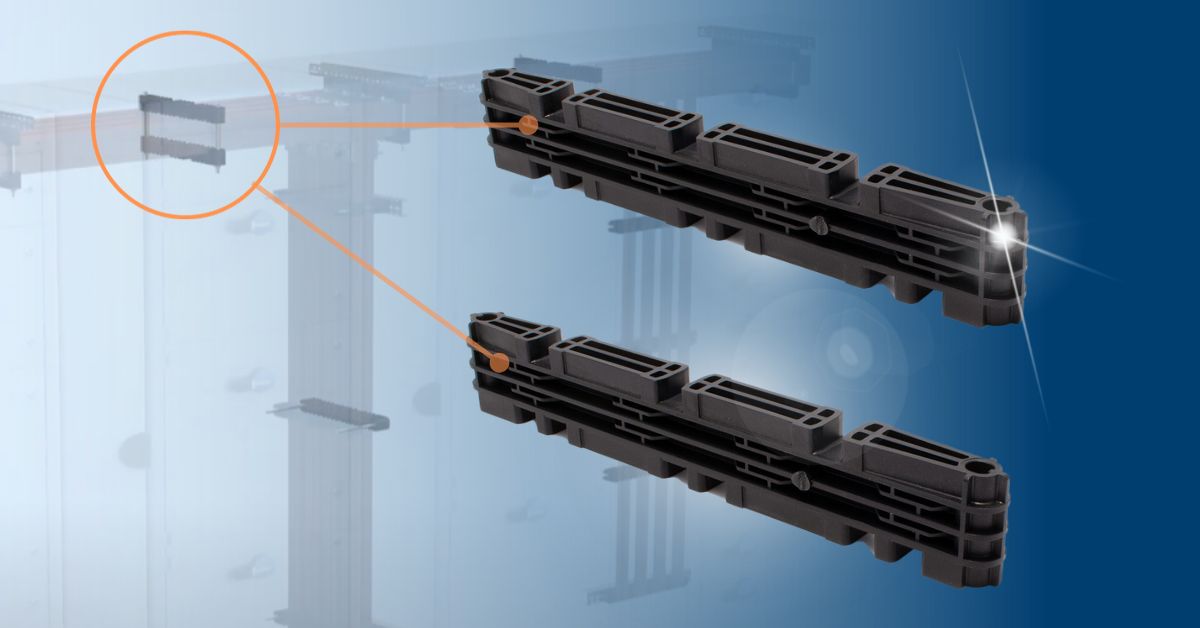

The French group SOCOMEC, leader in the control and safety of electrical networks, has chosen to use LATAMID 6 H2 G/30-V0HF1 for its SB C 15 busbar support.

The SB C 15 busbar is designed for three- or four-pole systems, both flat and vertical, with three conductors per pole. Thanks to the LATI material, it can transport currents of up to 6,300 amperes continuously, and up to 80kA in the event of a short circuit.

The compound in question is made of PA6 reinforced with 30% glass fibre and it is self-extinguishing without containing halogens or red phosphorus. UL has certified it for continuous use at temperatures of up to 120°C.

For even more demanding mechanical requirements, LATI offers self-extinguishing PA66-based compounds reinforced with 50% glass fibre: LATAMID 66 H2 G/50-V0HF1 and V0KB1.

Where moisture is a problem, non-hygroscopic solutions can be used. These solutions are based on PBT LATER (high temperature grades developed from PPS LARTON), or on new aromatic polyamide-based LARAMID T compounds.

The polymer PA9T offers levels of thermal and chemical resistance that allow busbar supports to be used in critical situations. For example, in battery charging systems, where there is a risk of thermal instability.

The evolution of electrical technologies requires advanced plastic materials able to cope with the challenges presented by strong currents and extreme operating conditions. In the transport of electricity, safety and efficiency is improved by the use of fireproof materials. The e-mobility industry can benefit substantially from these innovations, which make its systems more reliable and more sustainable.